Vincent

Technical

Sections: -Serial

Numbers/Production-

Photo Gallery of Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments -

Transmission

- Clutch - Magneto

- Tank/Seat - Suspension

-

Tools - Norvin

-

Electrics-

Carburetors

- Misc - Links

-Vincent

Parts/Services Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

Vincent

Transmission

-

One, Two, Three, Four

Transmission

Restoration, V Twin

All B, C, and D twin transmissions were basically the

same.

However, from 1946 to 1955, minor weak points in the

original concept

were discovered. The right hand crankcase casting was

modified in the

transmission area, in that additional meat was added for

greater

support of the shifter cam spindle and the shifter shaft

support

area. The cam plate shifter quadrant received a

support band

around the shifter shaft coupler tongs. The shifter

pawl

adjusting plate received over shift stop gears. The

Lightnings,

if ordered, had a higher low gear ratio than the standard

pedestrian

twins, G9/1 had 21 teeth, G11/3 had 27 teeth, that would be

the double

gear. The Shadow and Lightning shifter cam plate can

be

identified by a series of quarter inch lightening

holes. The

transmission counter shaft sprockets can be identified in

the following

manner. A road model sprocket is solid, except some

Shadows, not

all, were drilled for lightening, and had 21 teeth, giving

an overall

delivered gear ratio of 3.50 to 1. Lightnings were

thinner, to

accept the 520 chain drilled for lightening, and had 22

teeth.

Most Lightnings left the factory with an overall gear ratio

of 3.27 to

1. During the Korean war, some metals weren't

available.

Transmission gears suffered during this era, with low grade

gears. These gears can be identified by their number,

352.

Vincent transmission gears that are identified by

designation number

such as EN36 are of better quality, much

stronger.

If the motorcycle is in running order, it's a good idea to

take it

around the block a couple of times prior to tear down and

restoration,

to determine the preliminary condition of the

transmission.

Finding out how it shifts, and finding any obvious defects,

like

jumping out of gear, or excessive noise emanating from the

transmission

area, could be helpful later on.

Start your tear down by swinging the rear brake pedal

assembly out of

the way of the primary. Place the bike on the rear

stand.

Swing the front stands into position to achieve a four point

support

for the machine. Remove the clutch derby. Place

a drain pan

under the transmission area. Remove the drain plug

from the

primary chain cavity. Now go to the right side and

remove the

transmission drain plug, found forward of the transmission

shift cover

in the right hand crankcase side. The drain pan should

have a

capacity of four quarts. Now remove the clutch

assembly.

Inspect the area directly below the now visible primary

cover seal. If

dry and free from excessive oil, the replacement of the seal

probably

won't be necessary. When there's no drip from the

primary drain

plug, you can remove the primary chain cover. Inspect

the primary

seal again. It should be soft and flexible to the

touch, with no

hardness and no visible cracks to the rubber seal

portion. If the

seal appears suspect in any way, replace it.

You can now remove the primary chain clutch sprocket and the

crankshaft

sprocket. Inspect the retaining bolts of the

transmission

door. They should be drilled and safety wired.

Often

they're not. The reason for the safety wire necessity

is the fact

that the door receives a twisting torque caused by the lay

shaft gear

cluster trying to climb the main shaft cluster during

acceleration and

deceleration. The visible hex head cam plate indent

plunger and

spring assembly must be safety wired as well. The

twisting torque

has a tendency to loosen the retaining bolts, and loosen the

aligning

dowel in the bottom circumference of the transmission

door. Next

inspect the transmission's main shaft end clearance.

This is

easily done by taking the exposed main shaft and moving it

athortship

back and forth. The end clearance shouldn't exceed

.007. If

.007 is exceeded, write down in your tear down reference

notes, the

amount of shimming required to achieve a .005 to .007 end

float.

You can now go to the right side and remove the exhaust

pipes.

Remove the adjusting screw on the transmission shifter

cover.

Remove the clutch cable access cover. Unhook the

clutch cable

from the clutch release arm. Remove the clutch cable

from it's

clutch cable housing stop bore. Place cable out of the

way.

Shift transmission into neutral. Remove shift lever,

kick start

lever, and transmission gear indicator arm.

As the transmission shifter cam plate spindle is under the

battery

tray, it's necessary to remove items in order to gain

access.

Remove battery, battery strap, and the battery tray support

bolt.

You can now swing the battery tray up and out of the

way. Swing

the right hand foot peg assembly up and out of the

way.

Place a pair of vise grips on the shaft of the gear selector

positioning pointer. Feel for any slack or backlash

between the

shifter cam plate bevel gear and the bevel tooth

quadrant. You're

testing for excessive gear wear, and improper fitting of

parts.

The proper mesh of the bevel gear and cam gear is important

for a

nicely shifting transmission. Often the shaft

alignment through

the transmission cover is out of align, causing friction

between the

shaft and the outer cover, which every time causes an ill

shifting

transmission. This is especially true when using a

cover from

another engine, or a reproduction cover.

You can now remove outer transmission shifter cover.

Remove

kicker quadrant, inner shifter arm, and shifter pawl

assembly.

Leave the adjustable stop tab in place. Before removal

of the

adjustable pivot for the inner shifter arm, scribe it's

adjusted

position around the two washers. The pot metal slotted pivot

pin

support scribes easily. When the transmission is

reassembled,

this gives you a good starting point for shifter

adjustment. Now

you can remove the pot metal slotted support pivot pin

piece.

Next remove the circlip from the transmission main shaft,

and remove

the kicker ratchet assembly. Remove the clutch rod

assembly. The very first clutch rods were of one

piece. The

one piece assembly caused excessive wear to the throw out

arm.

The multi piece throw out rods reduced wear drastically, but

didn't

eliminate it totally.

After accomplishing all of the above, you will have total

access to

remove the transmission shifter mechanism dust shield.

This pops

out easily with a screwdriver in the slot provided.

The felt seal

is now exposed and can be removed. More than likely

it'll be

reusable.

Next remove the counter shaft sprocket nut. You'll

find the nut

is staked, probably in more than one place near the trailing

edge of

the nut thread in relation to the transmission sprocket

spline.

Probably the nut will have chisel marks from previous

removal, due to

the fact that most home tool boxes don't contain a large

enough

socket. When this is encountered, renew the nut.

Getting

rid of the ugly always makes you feel better. After

the nut and

the female dust cup are removed, you can check the counter

shaft

sprocket's splines. If the spline mating surfaces are

too loose,

it will cause a hammering action, which in time will

eliminate the

sprocket spline altogether. Not a good

thing. Max Lambky

11/5/10

Transmission

Restoration

V Twin (2)

Remove the safety wire bolts, securing the transmission bore

to the

left hand engine crankcase. Remove the shifter cam

plate indent

plunger assembly from the transmission door. With a

heavy duty

stubbie screwdriver, remove the shifter cam plate spindle

screw.

It's located at the top of the transmission in the right

hand engine

case, near the mating surfaces of the two cases. The

spindle is

usually staked. More often than not the spindle is

easily removed

without much trouble, but sometimes you need a scribe to

catch the

threads for removal.

You are now ready to remove the transmission gears and

shafts from the

transmission cavity. With a rawhide or rubber mallet,

from the

right hand side of the motorcycle, hit the mainshaft on the

end,

driving the transmission door from it's mating support bore

in the

engine's left hand case. Remove from the left hand

side, the

transmission door and mainshaft. Most of the time the

layshaft

will come out from the door, along with some gears.

The rest of

the transmission parts will find their way into the bottom

of the

transmission cavity. Don't worry about this.

Even with no

manual of any kind, the transmission will only go together

one

way. The only parts that now remain together are the

layshaft

bearings in the transmission door, the right hand engine

case, and the

two bearings of the mainshaft, one in the transmission door,

the other

in the right hand engine case. These bearings rarely

need

replacement. The two layshaft bearings usually require

heat from

a torch to remove. The layshaft transmission door

bearing is the

easiest, due to the mass of the door. The layshaft

bearing in the

right hand engine case rests in a blind bore. This is

the hardest

bearing to remove. The best tool to remove the bearing

is a valve

seat removing tool. It will fit quite nicely within

the radius of

the inner race nearest the engine case, when the lip is

expanded.

You can then use the knocker, and with minor heat on the

case, the

bearing can easily be removed. The mainshaft bearings

can be

removed with a half inch drift, tapping in a circular motion

around the

inner race. On the right hand case bearing, sometimes

it's a good

idea to, with a dremmel tool and a small rotary file,

relieve the stake

overlap. The transmission door main shaft bearing is

the thrust

bearing of the transmission. The bearing is captured

with a lock

ring nut on one side and the door housing bore shoulder on

the

other. This bearing is the aligning bearing of the

whole

transmission assembly to the engine cases. The lock

ring nut must

be made tight to insure proper positioning of the thrust

bearing.

The lock ring nut is keyed into position with a split pin,

or for the

US guys, a cotter pin. Drill the split pin hole

accordingly to

achieve this.

Install the shifter cam spindle, insuring that the spindle

reaches it's

shouldered stop. Place the shifter cam in the palm of

your left

hand. Note the indents on the outer edge of the cam

plate.

There are five indents, four of which are for positioning

each gear of

the four speed transmission. The fifth indent is for

neutral. If not marked with an end. It's the second

indent,

turning the cam plate in the direction of rotation.

Place the

neutral indent towards your body. Slide the cam plate

into the

transmission cavity, and marry the spindle pin to the female

bore of

the cam plate. Push upward. The bevel teeth of

the cam

plate should mesh with the bevel tooth shifter quadrant with

zero

backlash, before the top of the bevel gear on the cam plate

hits the

shoulder of the transmission cam spindle. If you can't

achieve

zero backlash by doing this, you must place a small shim

under the

spindle before screwing it home, or with a grinder, move the

shoulder

of the pin closer to the threaded end. Remove the cam

plate and

inspect the beveled gear. If excessive wear is noted,

the gear

should be replaced.

Next, inspect the shifter forks. One fork is female

and one fork

is male. First check for the straightness of the

fork. This

can easily be done on the table of a mill. Place the

fork flat

with the cam pin between the T nut slots. Check for a

90o angle

of the male shifting fork with a machinists' square.

Turn a

biscuit in the lathe from wood, metal, plastic, or anything

that just

fits in the female portion of the female shifter fork.

With a

second biscuit, 1/2" thick and a smaller diameter, you can

now check

the female shifting fork the same way.

Check the shifting fork pins for wear. Often you'll

find worn

flats 180o from each other on the pin. If you find

this to be the

case, the pins will have to be replaced. Sometimes

you're able to

remove the pin with a drift punch, turn the pin around, and

insert,

using locktight. Insure that you don't push the pin in

too

far. Strive to maintain it's original proud

position.

There are two reasons a restorer or mechanic gives attention

to the

transmission. The restorer often is only giving the

transmission

a thorough look-see, trying to ascertain whether all of the

parts are

serviceable, and will operate in an 'as new'

condition. The

mechanic is usually fixing a malfunction of some sort.

More than

likely the problem will be a broken gear, or a transmission

that won't

stay in gear, or a transmission that doesn't shift

properly.

Transmission gears should be inspected for missing teeth and

meshing

teeth.

The Vincent transmission has what is referred to as a

'straight cut

gear'. If the shafts of a straight cut gear mesh are

straight,

there should be no thrust of the gears, assuming that the

meshing teeth

are in good condition. When the meshing engaging teeth

of a

Vincent transmission become worn and lose the tooth's cam

chamfer,

which holds the gear in mesh, the transmission gear pops

out. The

thrust created by the worn tooth becomes greater than the

force of the

shifter cam spring loaded indent

plunger.

If the transmission tear down was for a restoration, inspect

all of the

gears and the four bushings for excessive wear and

condition. If

the transmission was torn down for repair, a more thorough

inspection

of all transmission parts will be necessary. If for

instance, the

transmission was popping out of second gear, more than

likely the

meshing teeth are beyond repair and the two meshing gears

will have to

be replaced. When the transmission is restored or

repaired,

always replace the right hand engine case seal. This

particular

seal receives the most abuse, and wears more quickly than

any other.

One other most IMPORTANT tidbit--when performing a

crankshaft out

restoration, where the engine cases are split, insure that

the

transmission bevel gear shifter quadrant is installed along

with it's

stop positioning spring.

It may be more convenient, and provide more access, to

remove the rear

carburetor assembly and place out of the way. The

early B's, had

the larger diameter generator, which may need to be removed

for access

to the cam plate shifter spindle. Max

Lambky 11/5/10

Transmission

Restoration

V Twin (3)

If you've gone through the previous steps religiously, and

all parts

have been thoroughly cleaned, inspected, and repaired as

necessary, you

are ready to reassemble the transmission and replace it in

it's

home.

On the workbench, assemble all of the transmission shafts,

gears,

spacers, shifter forks, and shifter cam plate. The

transmission

will only go together one way. Place the transmission

door in a

vise, clamping at the bottom where the aligning dowel pin

hole

is. Allow enough clearance so that the transmission

gear assembly

can be inserted into the transmission door. When the

transmission

is assembled in it's cluster, you can easily wrap your hands

around the

cluster and insert it into the transmission door. When

the

mainshaft and the layshaft are lined up and started in their

bearings,

you can take a rubber mallet and gently tap home. Turn

the

shifter cam plate, engaging low gear. Insert the

indent plunger

assembly into the transmission door, and turn hex

approximately two

turns, engaging two threads. The indent plunger and

the shifter

cam plate indent should now be in line. Insert from

the right

side, the shifter shaft into the shifter quadrant.

It's a good

idea not to depend on the shifter quadrant gear spring to

hold in place

during assembly of the cam plate bevel gear in proper mesh

with the

quadrant gear teeth. THIS IS CRITICAL. If the

mesh is one

tooth off, the forth gear shift will not be

achievable. Place a

pair of visegrips on the shifter shaft so that the weight of

the

visegrip handle provides additional help to hold the

quadrant in place

while assembling. Permatex the door area on the left

hand engine

case, using non-hardening Permatex. You can now remove

the

transmission cluster and transmission door from the vise,

and insert it

gently through the opening, which requires an up and down

manipulation,

so none of the gears or cam plate is disturbed during this

operation. There is a 'feel' when the mainshaft

assembly enters

the right hand side engine case bearing. Next, you

will 'feel'

the shifter fork shaft engage in it's bore, and lastly the

layshaft

entering it's bearing bore. You can now, with a rubber

mallet,

tap on the transmission door lightly. Do not tap on

the

protruding transmission mainshaft, as this will move the

gears and

rotate the cam plate, which is a no-no for proper tooth

engagement of

the cam plate bevel gear and the shifter quadrant bevel

gear.

Install two bolts in the transmission door, 180o apart, and

tighten. Now insert the cam plate spindle. If

the spindle

does not fall home to it's threaded end, the cam plate bore

is not in

align. Remove the cam spindle, and with a scribe,

feel, and line

up the cam plate. The cam plate will shift into

aligning position

easily. Reinsert the cam plate spindle pin. It

should align

and fall into it's threaded end. Screw the cam plate

spindle

home, and tighten. Do not stake the spindle at this

time.

Spindle staking is done after you're satisfied that the

transmission

shifts properly.

Tighten the plunger indent assembly. It's now time to

check and

see if the transmission shifts. While turning the

transmission

main shaft in the direction of rotation, go through the four

gears and

neutral, by turning the shifter shaft with the

visegrips. If

all's well you'll hear the spring loaded pawl plunger

clicking into the

cam plate indent. You should 'feel' when the indent is

engaged,

except for neutral, and if all's well, you should 'feel' a

geared power

transmission from the left hand mainshaft to the right hand

counter

sprocket spline shaft.

You can now finish bolting everything together. Use

your Vincent

Owners Handbook for transmission shifting

adjustments. Max

Lambky 11/5/10

Adjusting

the Gearchange:

There are two things to fiddle with to make a proper adjustment of

a

twin

transmission, whether it be an original 4 speed, or an after

market 5

speed.

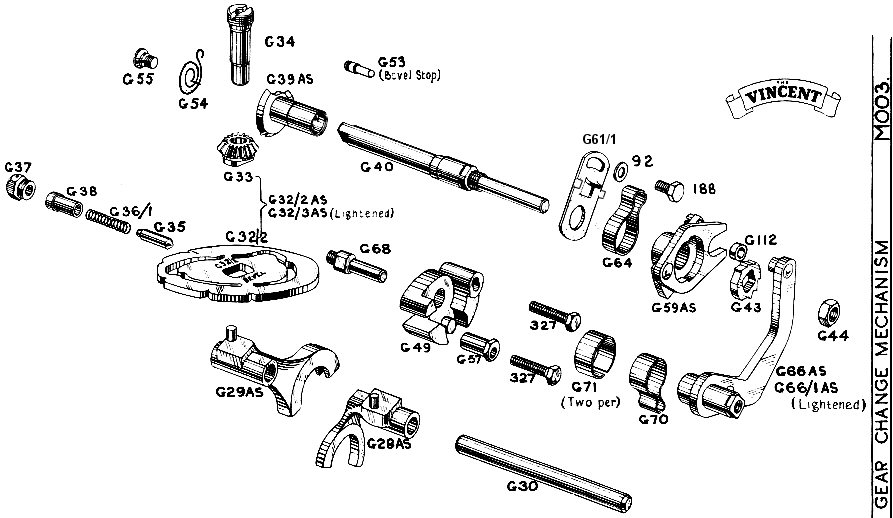

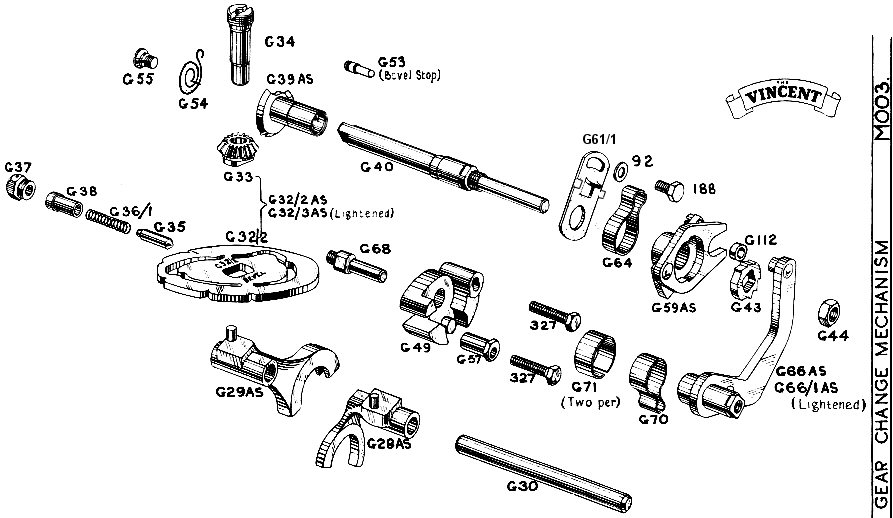

The two being the G57 and the G61. When the transmission is

in

neutral,

and the shift lever is in a relaxed position, and the G70 spring

is

supporting

the weight of the G66AS shifter arm, and the exterior foot shifter

arm,

the picture should be identical, i.e., the distance between the

outer

male

shifter pawl and the inner female shifter pawl, both for the

engaging

side

for low and the engaging side for second. One other 'must

do'

thing

is to insure G61 is pivoting on the shoulder of G40. It's

easy

for

G40 to slip away from it's shoulder on it's support bearing.

Adjusting

the Gearchange:

There are two things to fiddle with to make a proper adjustment of

a

twin

transmission, whether it be an original 4 speed, or an after

market 5

speed.

The two being the G57 and the G61. When the transmission is

in

neutral,

and the shift lever is in a relaxed position, and the G70 spring

is

supporting

the weight of the G66AS shifter arm, and the exterior foot shifter

arm,

the picture should be identical, i.e., the distance between the

outer

male

shifter pawl and the inner female shifter pawl, both for the

engaging

side

for low and the engaging side for second. One other 'must

do'

thing

is to insure G61 is pivoting on the shoulder of G40. It's

easy

for

G40 to slip away from it's shoulder on it's support bearing.

When engaging the male female shifter

pawls,

the

engagement of the pressure flats of the pawl should be

simultaneous

with

the contact of the relief's of G59AS and G43. The

adjustment of

G61

pretty well takes care of the pressure flat adjustment, and G57

pretty

much takes care of the relief of G59AS coming in contact with

G43

prematurely.

I've found that when you play with one adjustment, more than

likely

you'll

have to play with the other adjustment. When it's right,

you

should

be able to take the foot shift lever and visually observe the

point, or

apex, of G59AS, engage G43 in it's cleavage point,

simultaneously with

pressure contact point, and relief contact point. The most

common

mistake in adjusting the shifter, is that the relief contact

point is

premature.

It's fairly easy to adjust a transmission to shift well,

assuming that

when in neutral the G40 has very little backlash movement.

If

there

is excessive backlash, proper shifting cannot be obtained.

A well shifting transmission has a lot to

do

with

mass. Each shift requires a mass from a dead stop to

accelerate

over

a distance, and come to an abrupt stop. The mass in a

standard

Vincent

transmission, which is a four speed, that has to be started and

stopped,

is approximately 20% more than the after market five

speed. To

get

five speeds in a four speed gear box, obviously the gears will

be

thinner,

thereby lighter. There are two shifter forks in the four

speed,

and

three shifter forks in the five speed. The shifter forks

are much

lighter in the five speed than in the four speed, and much

stronger, as

they are made from steel. There is less movement in the

gear to

make

it shift in the five speed than in the four speed. The

large

engaging

dogs of the five speed, not only allow a better hold in angle

cam grind

(preventing jumping out of gear), it also is much better in

design,

which

enables the mesh of the gear dogs to actually relieve the cam of

the

shifter

fork from it's duties, and the force of the meshing dogs at this

point

actually turns the cam plate, not the shifter mechanism.

The five

speed is a much better design than the four speed in this

respect, as

it

allows slight roll off throttle shifts without clutch

disengagement.

The four speed transmission, when raced,

tries

desperately to reduce shifting mass by lightening the G32/2 cam

plate,

and the G66AS shifter arm. It's a good idea to

lighten the

G66AS when installing a five speed. Max Lambky

4/5/10

Adjusting the

Gearchange:

The

alloy block (G49) swings in an arc. If you loosen the two

bolts

(327)

and turn the eccentric hollow bolt (G57), you will find you are

able to

turn to high point and low point, the starting position would be

the

Middle

of this travel, then tighten bolts. Once you have placed gear

indicator

shaft in Second gear, you turn slightly the shaft to have

equal

gap

either side of that segment by altering the position of the small

plate

(G61), some have " Ears " some not, this was a modification or to

suit

those gear changes which were hard to adjust. The ears

restrict

travel

to not over or under shoot the gear engagement... at times one may

need

to bend the ears slightly. You must make allowances for any

Play

or Backlash .. or find another gear shaft with good segment,

etc.

Once you have done this and satisfied, you select the best

position in

gearbox by turning rear wheel slightly, so you can Swipe through

All

the

gears with gear indicator lever from bottom to top. It

may

take a bit of fine play to achieve. Place in Second gear

after

with

indicator. The reason for this is so you can with Gear

Change

Lever

select up or down in One clean movement. The full

travel of

lever must hit the Stop in alloy block Both directions. If

it

doesn't

and the gear falls in or fails to engage, then you alter

slightly

the position of alloy block to suit. This takes longer to

explain

than do. Mike White 5/1/09

Quaife 5 spd

Gearbox:

http://www.quaife.co.uk/shop_image.cfm/image/681/product/Vincent%205-speed%20Quaife%20gearkit

Glad you could read the Issue 3 G/A drawing

dated

27.03.03. More info below:

If it's of any interest, here are the ratios

of the Quaife / Surtees 5-speed

Vincent

box:

1st 1:2.46

2nd 1:1.61

3rd 1:1.34

4th 1:1.075

5th 1:1

...and the drive sequences (numbers refer

to

the

two end digits of the Quaife part numbers on the G/A drawing):

1st Selector 20

Leftward

28 -> 29 -> 13 -> 09 -> 18 -> 07

2nd Selector 20

rightward

28 -> 06 -> 14 -> 13 -> 09 -> 18 -> 07

3rd Selector 21

rightward

28 -> 06 -> 16 -> 18 -> 07

4th Selector 22

leftward

28 -> 06 -> 03 -> 13 -> 09 -> 18 -> 07

5th Selector 22

rightward

28 -> 06 -> 07

... and the small items' descriptions:

Item 2 (2 of): thrust washer (however, this

part

shown next to layshaft gear A-1E1-18 absent on my box, as that

gear is

a driven interference fit to layshaft spline tapers).

Item 172: needle roller bearing

Item 292: C-clip

Item 586: needle roller bearing

Item: 675: seal

A-1E1-04: thrust washer

A-1E1-05: plain bush

A-1E1-08: thrust washer

A-1E1-11: plain bush

A-1E1-12 (2 of): thrust washer

A-1E1-15: plain bush

A-1E1-17: plain bush

I guess A-1E1-18 wasn't manufactured as one

with

the layshaft as they couldn't have machined the dogs that

way.

Box main parts shown at

http://www.quaife.co.uk/shop_image.cfm/image/681/product/Vincent%205-speed%20Quaife%20gearkit

Phil Blakeny 6/9/08

Comet Trans:

Correct

one

is BAP. The B52/CP/GB boxes are all the wrong sizes

cases; shorter shafts and different gears/selectors from the pre and

post-war

Comets. One can make expensive mistakes buying these boxes in

the

belief they are BAP ones. Don't ask me how I know... Peter

Barker

4/15/08

Burman Drawings: http://vincenthrd.se/skisser.php

Various Grease/Oils for Burman Trans.:

* Castrol Spheerol L-EPO Semi-fluid

self-levelling

grease suitable for centralised lubrication systems and grease

filled

gearboxes.

* Penrite Semi-Fluid grease for Burman

boxes. It is best to do it on a warm day (or lace the

container

in

a bowl of hot water) otherwise it takes an eternity to

fill.

Do not try to run the bike for a few hours after filling as it

takes a

while for the grease to find its own level. Some people add about

50 ml

of light oil too.

* Millers of Brighouse sell a grease

Delta

EP000 in 3 Kg drums for a tenner. See their website

for

depots.

Very liquid.

Burman Gearbox

Oil:

It can be a cause of rapid bushing, etc. wear if the

grease

is too thick and does not flow

readily.

The

gears will tend to cut a track through it after which it does

not

flow into them continously. Also it will not enter tight

bushing

clearances. I suggest a small quantity of soft

grease

followed by sufficient 90 wt. gear oil to

acheve

the correct level. This way the soft grease gets carried

into

any leakage paths sealing them while the job of real

lubrication

is delt with by the gear oil . This works

nicely

in our Meteor and if not overfilled it

rarely

shows

any seepage. Sid 6/18/07

I have a Comet

with

a Commando gearbox. I fitted a

main

shaft seal from the Spares Company so that I could use automatic

transmission

fluid in the primary drive. I mounted the gearbox sufficiently to

the

left

so that there was room behind the clutch for a plate carrying an

oil

seal.

I was able to do this as I had mounted the gearbox in a fixed

location

and fitted a twin chain tensioner blade, suitably narrowed

in the

primary chaincase. All the springs were removed from the Vincent

ESA

and

the two halves welded together, the shock absorbtion being handled

by

the

rubber inserts within the standard Norton clutch. This results in

a

rigid

assembly and a very sweet transmission. There is absolutely no

justification

for fitting a triplex chain to a Comet, there's isn't enough

torque

there

to require it. Roy Cross

It is possible to get the gearbox

out of the Comet without

dismantling

the

whole machine though obviously the clutch will have to be removed.

It

all

depends on the two chain adjuster bolts that allow the gearbox to

swivel

backwards and forwards for primary chain adjustment. Ideally all

you

need

to do is to unscrew these two bolts and remove the gearbox

mounting

bolts

and with a lot of cursing and 'ackling' (wriggleing about) it will

come

out. Warning ! Unfortunately it is usually impossible to remove

the

chain

adjuster bolts as in service the working ends that bear on the

lower

gearbox

mounting bolt bell out. Any attempt to remove them will strip the

threads

in the gearbox casing. However I have managed to remove and

replace

several

Comet gearboxes over the years with bolts that were belled out. It

is a

tedious process requiring much patience. What is needed is to keep

adjusting

the positions of the adjuster bolts relative to each other and by

trial

and error, so far, I have always found a position where I can

wiggle

the

gearbox out. Tightening of the Gearbox is usually the drive side

layshaft

bearing. Heavy

grease never gets to it hence the advice to

put

in the odd spoonfull of engine oil. Hugo 3/10/07

Pre-war, the Burman

BA-

BAP

traansmission was made with

three

sets of gears:

* HS, which is the set we know on the post-war

Comets.

* LS, which appears to be Trials: only the

constant

mesh (4th.) gears differ from the HS.

* TT gears as fitted to competition models.

Post war, only the HS ratios seem to have

been

manufactured, and as we know, the Flash used the Albion box, for

which

a wide selection of gears were available. I do not

consider

either

the HS or TT gears were really the correct ratios for their

respective

uses. It would, of course, be possible to redesign each set,

which

would

probably mean replacing virtually every gear in the box.

However,

for road use, there is an interesting compromise based uniquely

on

pinions

which once existed: to use the standard 1st. and 2nd. pairs

which

presumably

exist in your present box, in reasonable condition, with the TT

4th.

and

3rd. pairs of gear- that is, changing 4 pinions. This

would give

ratios of 1:1, 1.16, 1.45 and 2.3, or 100, 86, 68 and 43%.

Bruce McNair 2/9/02

Pre-war Burman

Transmission

spares list:

http://www.btinternet.com/~paul.wirdnam/sq4/1930/burman_frameset.htm

Synthetic oil

is

banned

from being used with our kind of bearings, simply because the

coefficient

of friction is too low for the rollers and balls to rotate, causing

them

to skid, and wear with flats on them. Any one out there have any

Long

term

usage with Synthetic, e.g. Mobil 1 ? And had a look at the results.

Trevor

A quick check for gear

changing

problems is to change gears with one hand - with the

bike on

the rear stand - whilst restraining the indicator lever G81's travel

by

holding the indicator with the other hand. When the gear lever

has

reached the end of its travel carefully check to see if there is

anymore

movement of the indicator lever to fully engage the gear being

selected

by moving the indicator lever in the same direction it was

travelling.

If there is any more movement of the indicator lever required then

the

camplate G32 is not travelling far enough by gear lever operation.

If this symptom can not be cured by adjusting the selector

mechanism

then the cast alloy block G49 needs opening out with a file to

allow

more

travel. Check that this is infact the problem by carefully

adjusting

G57

stoplate adjuster so that more movement of G81 is required to

engage

both

3rd and 4th gear.

This will prove the need for the block to be opened out - a

fairly

simple

job with a file and G49 in a bench vice 'a little at a time' till

you

have

the right amount of travel - being careful to remove the metal off

the

place on G49 that stops the travel of the gear lever or maybe a

little

off both stops with G57 in the centre of its travel ( to make

allowance

for future adjustment). G49 has a concave shape where the metal

has to

be removed - there is no need for this shape, a flat surface is

all

that

is required to limit the travel of the gear lever.

I have had to carry out this job on at least 3 separate bikes

after

which the gear change has been transformed - having giving the

gear

lever

just that little extra travel.

I have also discovered the importance of adjusting the battery

carrier

nuts E80 to compensate the load on the pivot bearing plate G50

when the

foot rest hanger bolt is nice and tight for a really nice gear

change.

If there is any stiffness in the gear change when the engine is

hot -

try

slackening off the hanger bolt just to see if this is the

adjustment

needed.

If so, adjust the 2 E80 nuts outwards and pinch up the foot rest

hanger

bolt again and carry on riding. Andrew

Rackstraw

8/14/00

When you get a situation where the box jumps

out

of top gear as your try to grab a handful , the usual

reason

is that the detent did not go into its position on the camplate,

this

is

the positive position. On some later machines you can find

that

the

detent Cannot even get that far. The G39 being stopped from rotating

into

position by the bevel stop pin. This can only be checked on assy.

with

the gearbox assembled and with the detent out, look into hole to see

where

the camplate is. If you have had a problem with top gear

jumping,

this is the cause. Trevor 8/14/00

Denny Delzer asks why his gearbox jumps out of second gear ? This

means

that the detent is not sitting

in

the

camplate perfectly, this could be for two reasons.

1 On changing gear the gear pedal is depressed too lightly ,

allowing

the gear to change but the detent does not sit in position.

2 The set up of the gearbox does not allow the detent to sit in

position.

Even if you have as you say NOS parts or good condition parts in

the

box, this is not a reason to say there is nothing wrong.

So what you have to do to check out the set up, is to remove the

detent

and visually check if the camplate is in position, when the box is

in

second

gear. If it appears to be, replace the detent spring, and

test

ride.

If the problem still occurs you have a problem with the set up.

The

only

way to check then, is to use my checking fixture and sort

out the

problem. I won`t begin to tell you what could be wrong. I`ve

lost

count. Trevor 6/16/00

Improvements to

shift

quality

Many - even most of the Vincent

motors we have dealt with in our work lack one small but extremely

valuable

Works up-grade dating back to the very early years. A simple

looking

alteration first suggested by one of the fine road-testers active

then,

one Bob Brown. Very keen and dissatisfied with the tendency to

over-shift

present in too many units that he rode -Bob came up with the notion

of

adding restraining tabs or ears to both sides of the pawl carrier

centralizer

plate G 61. This became G 61 /1 with the addition of two projecting

motion

stops brazed one to each fore and aft edge. So utterly simple

it

seems, yet properly positioned truly worth more than its weight in

Gold.

Perhaps because it is not so drawn in our B/C Parts

Books

yet

carries the corrected part number. Few have picked

up

on it and the magic it performs. My first exposure and

explanation

came to me way back in 1953 while shoping at the Works Spares

counter

where

the modified piece was handed me and called the Bob Brown

Special.

Friendly chap behind the counter there confided that I'd surely want

one

of these as he dropped it into me waiting hand.

There is a subtle touch to getting it swung just so in

order

to

derive the best results out of those metal stops that Ill

try to

convey to you my friends. The aim is to snub off excess

inertia /

momentum imparted to the spinning cam plate during a too

spirited

shift . This energy tends to rotate the plate past its next

notched

position -- forcing excess rotation to drive the plate - lifting

the

indexing

plunger up out of that desired notch and so allowing further

rotation

towards

- or into the following ratio selection. Over selection

results

. My experiance when fettling these pieces is to allow the ratchet

to

closely

approach - not enter fully - the up coming notch. Notice my

word

choice carefully . Closely approach only and Not fully enter the

cam

plate

notch. Thus the tab contacts and acts to slow/snub off

the

excess speed, to where the spring driven detent plunger can

take

over control and deliver sweetly to the bottom of the notch,

that

unwanted momentum already absorbed in the slight flexing of

the

arresting

stop. Only the spring pressure remains to fully seat the plunger

into

it's

homing notch. Barely any of the shift lever thrust and

rotational

energy exists in the plate as it enters the edge of the notch

slope.

Duplicated in both directions and I've seen very

little

need to bend the stops much, and the shift becomes dead reliable

and

pleasing

beyond words. Much of the ease and sweetness is dependant on full

clutch

release, and I shall delve into that clouded subject

in my

next effort , however let me say that after all these

decades

I am still and ready to prove that the original Vincent

clutch

can

deliver better feel and function than a

multiplate

conversion

for greater mileage and less parts wear than any in my

experiance.

S.M. Biberman 21 Mar 2000

return to thevincent.com

Adjusting

the Gearchange:

There are two things to fiddle with to make a proper adjustment of

a

twin

transmission, whether it be an original 4 speed, or an after

market 5

speed.

The two being the G57 and the G61. When the transmission is

in

neutral,

and the shift lever is in a relaxed position, and the G70 spring

is

supporting

the weight of the G66AS shifter arm, and the exterior foot shifter

arm,

the picture should be identical, i.e., the distance between the

outer

male

shifter pawl and the inner female shifter pawl, both for the

engaging

side

for low and the engaging side for second. One other 'must

do'

thing

is to insure G61 is pivoting on the shoulder of G40. It's

easy

for

G40 to slip away from it's shoulder on it's support bearing.

Adjusting

the Gearchange:

There are two things to fiddle with to make a proper adjustment of

a

twin

transmission, whether it be an original 4 speed, or an after

market 5

speed.

The two being the G57 and the G61. When the transmission is

in

neutral,

and the shift lever is in a relaxed position, and the G70 spring

is

supporting

the weight of the G66AS shifter arm, and the exterior foot shifter

arm,

the picture should be identical, i.e., the distance between the

outer

male

shifter pawl and the inner female shifter pawl, both for the

engaging

side

for low and the engaging side for second. One other 'must

do'

thing

is to insure G61 is pivoting on the shoulder of G40. It's

easy

for

G40 to slip away from it's shoulder on it's support bearing.