Vincent Carburators

The subject of rich discussion:

Click for

Blow-up

of Standard Amal Carb for Vincent

Tuning

276/289/229 Amal Standard carbies:

http://www.britcycle.com/Manuals/premonobooklet.pdf

5/1/2010

If you do use

an 'ultrasonic

cleaner' watch the process very closely... ultrasonic cleaners

dissolve

aluminum... after the crud is gone... you Have to know when to

take the

componant out or you will have surface degradation. Many

modern firearms

have numerous aluminum

componants. We have had problems with this issue in our

shop...we

no longer use ultrasonic cleaning if all of the componants do

not jump

to the magnet... Dave R. 3/10/10

read next post

Not if you use the

right

cleaning solution.

http://metal-cleaning.alconox.com/cleaning_aluminum.htm

John

Mead 3/10/10

Sticking slides seem to occur in about fifty to

sixty

percent of the Concentrics

coming through the shop. In paired carbs it may be one or both.

In general

sticking occurs toward the top of the slides travel range but it

can also

occur at other points in the travel. It invariably occurs in or

close to

the plane of the carb bore.

First, having removed

float

bowl, cables, choke etc it's necessary to thoroughly clean the

slide and

bore with carb cleaner and if required a worn kitchen scouring

pad to remove

any clinging grit or debris. Blow everything out with

air. Unless

there is other work to do on the head or flange the carb

body(s) is left

undisturbed attached to the head. Now test the slide by

passing it down

the slide bore. It should drop freely. If it hangs at any

point then grasp

the top of the carb slide bore between thumb and forefinger

starting at

right angles to the carb bore and press firmly. Surprisingly

often the

slide will now drop freely on it's way. The slide bore can

easily be slightly

deformed just by such hand pressure. By varying the pressure

point around

the slide bore to see where it best frees up the slide the

plane of the

deformation can often be determined quite accurately by this

method. Upon

release of the thumb and finger pressure the bore will spring

back to it's

deformed shape so this is only useful for determining where

and in what

plane the bore is deformed. If this method fails to free slide

then there

has generally been sufficient deformation to produce

noticeable wear on

the bore and/or slide. Make a visual inspection down the bore

and on the

slide. Most times you will see a highlight polished or scuffed

area running

vertically in the bore or on the slide which will tell you the

plane in

which it is sticking. It is nearly always along or close to

the plane of

the carb bore.

Now comes the tricky bit

which requires

some practice and "feel". Having determined where applied

pressure on the

bore frees the slide wrap the top of the bore with cloth or

cardboard and

using a suitably sized pair of channel locks squeeze the

bore at

that point to permanently "reshape" it. It does not need a lot

of pressure

to do this so it should only be done very judiciously. Try the

slide again.

You will soon tell whether it moves more freely or not. Repeat

this process

very carefully and at different points as needed until the

slide drops

freely. Usually this takes about fifteen to twenty minutes to

achieve.

Once the slide drops freely it will continue to do so without

problem.

Now I know to some of you high tech purists this may all sound

rather uncouth,

brutish and haphazard but after just a little practice one can

become very

exacting and accurate in the technique both from the

perspective of where

to apply pressure and how much to apply. Only in the rarest of

circumstances,

and sadly often where the owner has tried to "fix" things and

really buggered

things up, is it ever necessary to remove metal from either

the slide or

the bore. Doing so is very undesirable and merely accentuates

any wear

characteristics in the performance of the carb on reassembly.

Other points regarding

concentrics.

Eighty percent of the time the float bowl leaks because it has

been overtightened

on the gasket and, as described by Max, the bowl flange

becomes distorted

with the screw hole tabs being raised upward. Easily cured

with judicious

use of a plastic mallet and flat file. Sometimes the float

will stick because

either the new gasket tends to trap it (trim accordingly) or

the ends of

plastic pivot holes on the float (particularly new ones) foul

the casting

of the bowl. File a couple of mms of each side of the float

pivot taking

care afterward to make sure the holes remain fully open and

the float spindle

turns freely in them.

Invariably when

customers

complain that they can't get the bike to idle properly (all

else being

correct) it is due to the pilot jet being blocked in one or

both carbs.

The pilot jets on concentrics for some reason seem to block up

very easily

with gum, particularly if the bike is not used for any length

of time.

Cleaning them needs care. Blowing with air or squirting carb

cleaner into

the pilot air screw hole generally does not unblock them.

Cleaning the

jet properly can only be done by the careful use of the

correct size micro

drill bit fed and twisted carefully by hand through the pilot

air screw

hole and on through the jet orifice. Again this takes practice

and care.

timothy holcroft 3/10/10

Sticking

Amals : Bolting

a flat steel plate onto the carburetor flange prior to honing

the carburetor

bore isn't recommended. If one were to do so, when the

crushed flange

is released from the carburetor flange, the high spot areas

which were

honed away now become low spots. If you were to use a

flange in the

process, you would first have to flatten and true the carburetor

flange

prior to honing the carburetor slide bore. It's not

necessary, in

fact it's a waste of time, to prebolt a flange prior to

honing.

I've done this probably 30 or 40 times, so I know from personal

'hand's

on' experience what works and what doesn't.

A further explanation as to

why

the ears of the flange bend and distort with a thick paper

gasket:

The surface area of the paper gasket around the carburetor

opening has

more area than the paper gasket material around the manifold's

studs.

When the pressure is applied, pulling the flange surfaces

together with

the nuts, the paper gasket around the stud area, which is

less, crushes

more easily, thereby bending the ears during the tightening

process, and

distorting the carburetor body bore. Using a very thin

gasket and

two flat surfaces, distortion is virtually eliminated, even

when over torqued.

New or recently rebuilt

Amal carburetors

that have been cleaned properly, do not stick.

Carburetors that have

many hours on them, and are ridden by individuals who don't

necessarily

hit the throttle stop from stoplight to stoplight, form a

resin buildup

above the top of the carburetor slide around the carburetor

slide bore.

When the carburetors are open to full bore, and find their way

into the

top of the slide bore where they're not normally run, the

resin buildup

causes them to stick sometimes. I've never heard of a

new set of

Amal carburetors sticking when properly installed, i.e., flat

flanges and

free running cables. Problems only arise after many

hours of use,

or after an inexperienced fettler has been at it.

Max Lambky

3/10/10

Amal

carburetors have

a tendency to bend the flange

ears and

sometimes distort the slide bore.

The fix should be to make the slide fit the bore by truing the

slide bore

with a brake cylinder hone. Don't sand or polish the

carburetor sleeve,

as this will cause an improper clearance between carburetor bore

and cylinder

sleeve. With a large flat file, dress the flange face

flat.

You'll notice that high spots will appear on the outer convex

portion of

the ears. This is due not so much to over tightening, but

to the

use of a too thick gasket. It's also a good idea to check

the manifold

flange as well, for flatness. Correct as necessary.

For best

results make your gasket as thin as possible. I use the

glossy cover

of motorcycle magazines, and a bit of Permatex. Max

Lambky

3/10/12

The classical

method

for setting remote floats

(e.g. on GP carbs) is to make up a bottom nut with a piece of

capillary

tubing attached, and see where the fuel level actually is. On a

GP it should

be 1/8" below the centreline of the pilot jet, and I have always

assumed

it will be the same for a 289 (which is what I use) and for any

other Amal

carb. I did not do this for my twin since it would have

meant making

two different bottom nuts, but following a hint from Big Sid,

realised

that my front plug was consistently sooty (not oily) and since

the jetting

etc was identical front and rear, this was probably because the

float level

was too high on the front pot. So I rotated it downwards first

1/16" -

smoother running - then another 1/16" - as near as damn perfect.

It completely

transformed the bike, particularly in traffic and at low

speeds.

Moral of story: however much faffing about is involved, it is

well worth

while. A Vincent with two identical pots is a FAR nicer machine

than one

without, and provides a positively liquid power

delivery. Tom

- Sunbeam 3/10/10

I use 930's

on my '49 shadow and get good starting and running. I did some of

the mods

described in your URL but not the one about boring out the low speed

jet.

I didn't want to get that invasive. I reset the fuel level and I did

cut

away half the fuel feed nozzle. I figure the fuel level

setting is

what concerns the engine and carb for proper operation and measuring

that

is more accurate than measuring

the float position. If one float weighs a little more than another

or has some fuel in it or dirt on it , it may measure in the right

place

but the fuel level won't necessarily be right. I gently clamped just

the

float bowl with float and needle installed level in a vise and fed

gas in the inlet via a tube and funnel until the float stopped the

gas

feed. The fuel level should be close to .2 inches below the rim of

the

bowl

sans gasket and is easily measured unlike a monoblock . You may need

to hold the float hinge down the way it would be when

installed clamped

under the gasket by the body. Adjust the fuel level as described by

heating

the bowl (after you empty it!) and using a drift to move the

brass

insert that houses the needle valve and recheck the level. This was

wrong

on both my new carbs. One was so far off the tickler pin

wouldn't

reach the float so I couldn't prime that side. Once the fuel depth

was

raised the float came up higher and I could prime it properly.

I

run the needle in the lowest setting and it starts easily even

at

32 degrees F. Mike Hebb 3/10/10

Here is what I have been

using in my 30mm Mikuni round

slide Carbies:

1. Main Jet #190

2. Pilot Jet #45

3. Needle Jet 159

Q-2

4. Jet Needle 6DH4

5. VM34/110 2.5

6. Air Jet BS30/97

2.0

7. Fuel Needle VM34/39

3.3

8. I use two No.

002-351

Cable Type Starter Systems connected to the standard Amal choke

and splitter.

I think 32mm Mikuni's

are

a little large unless you are going for real high speed

performance and

have the correct camshaft and gearing. Even my 30mm may be a

little larger

than necessary. Even 28mm are larger than the Shadow carbs and

Mikuni's

certainly have better flow, size per size, than the old remote

float Amals.

All and all, they have been very reliable and run sweet when

tuned in.

Ken Smith 12/7/09

Throttle Slide Clearance: The

seal

is made by "sucking" the slide against the body at the back. What is

important

is 1) that the slide will slide easily, particularly when closing

and 2)

that the front and back faces of the slide are not worn,

particularly the

back (engine) face, because then it won't seal against the body in

the

mid-range. Better safe than sorry, but I seem to have about 2

to

4 thou on such slides I have that are new. The upside of larger

diametral

clearance is safety. The downside is that there is more rattling

room and

wear is faster. It is fastest on plain brass slides, slower on

chromed

ones, for obvious reasons. Sunbeam 11/12/09

389 Monoblocs were used on the "D" with the float

bowl

on the left and 689 Monoblocs

have

the float bowl on the right. John Mead 7/27/09

With modern

fuel the

only way to set your carburation up properly is either use a

rolling road

or buy a real time air fuel

ratio meter.

I have bought a Luminition kit that runs off of a 12volt

supply.

All you have to do is poke the sensor up the exhaust pipe and go

for a

ride, the display is easy to read and is real time via the wide

band sensor

(remember you only get use full data when the engine is under

load).

The results are very intrusting and on all the Vins I have tried

so far,

I have found them all to be running very rich on the main

jet.

My bike is running 8.5/1 compression ratio with a good set

of 276

carbs and I am down to a 140 main jet and have done 1500 miles

like that,

and that included a good thrashing around the TT course last

year.

You can buy the kit for around £250 so if a few of you get

together

and split the cost it would work out cheaper than a couple of

hours on

the dyno. Andy 7/8/09

Amal parts:

www.hitchcocksmotorcycles.com

Milnar

Amal GP2

parts: http://www.manx.co.uk/pdf/MPL-T3_GP2.pdf

Bruce

Metcalf

I do recommend the fabrication

of a float fuel level gauge

comprising a bottom nut drilled and tapped to take a needle jet,

over which

a length of transparent fuel line of the kind used on model

aircraft motors

can be slipped. When this is held vertically against the carb

and the fuel

turned on, the level will correspond to that within the float

chamber,

which is invisible, and can be checked against where it should

be in relation

to the bottom of the pilot adjuster screw and its threaded hole.

An invaluable

little tool, no matter what method you use to rectify the fuel

level.

Prosper Keating 5/21/09

K&N Air

Filter for

a Comet:

http://autoparts.thecarconnection.com/auto-part/993327-kn-air-filter-k33ru0160

(K&N

- K33RU0160, RU0160)

The Amal spec

sheet

for 1955-1961 says for D Prince

and Shadows

that

main jet should be 280, slide should be a 4 (Not 3), pilot jet

30, needle

jet 389/063 in the middle position (3), needle jet 106, no

letter at all

for the needle itself. David Stein 4/20/09

Sealing Inlet

manifolds:

If using the stub-mount carbs, I use a bit of plumbers teflon

tape. Fuel

resistant and very thin and you can apply as many layers for a

nice snug

fit before clamping. Prior to switching back, I had flange mount

and would

just use some wet/dry paper on a piece of glass and true the

surface by

sanding the face. John Romano 3/26/09

Amal 930's for Vincent

Twins:

Here is the setup for 930's (30mm). >This gives 1st kick starts

and perfect

throttle response, with text book plug readings (Champion

#120).

These are the late model concentric w/#25 pilot jets built in.

Starting

from the top: #622-122 throttle needle in lowest position; #3

throttle

valve (slide); #106 needle jet (use the one with the cross hole in

it;

#180 main jet. set the pilot air screw around 1 turn open, then

adjust

to your bike's requirement. Set the throttle stop so there is a

1/16" gap

at the bottom of the slide and adjust to your bike when

warm.

John Ulver 12/16/08

Period Feridax

Throttle

Lock: From memory I think

it uses

a Wilmot Breedon (or similar) car lock and the key could come from

a classic

car specialist.

I think the number is stamped on one of the

castings

- something with a two letter prefix eg FP256. I have seen

traders

at Autojumbles with racks of the keys.

Chris Chant 7/23/08

Carburator Finish:

Rear carbs, die castings in zinc alloy, were silver painted. Front

carbs,

sand castings in brass, were cadmium plated. Later die cast carbs

weren't

even painted. Sunbeam 6/9/08

One option is to paint your carbs

with Eastwood's "Carb Renew," item # 10187Z (silver).

http://eastwood.resultspage.com/search?p=Q&ts=custom&w=carb+renew

Bev Bowen 6/9/08

Slide

Sleeving:

Alverstoke Restorations in UK bore the body and resleeve the

slide in brass

to suit, about $80 and 7 day turnround. Plus Atlantic crossing

presumably.

I've never heard of anyone using steel. But a common

misapprehension is

that the hard parts wears the soft. It's the reverse. The soft

part holds

particles of grit still while they wear the hard part away. A

wooden brake

block would last longer than the farm cart did. Replacing the

iron tyres

on which it bore kept blacksmiths in regular employment. It's

the same

mechanism on which the grinding wheel is based. Sunbeam

(?) 5/27/07

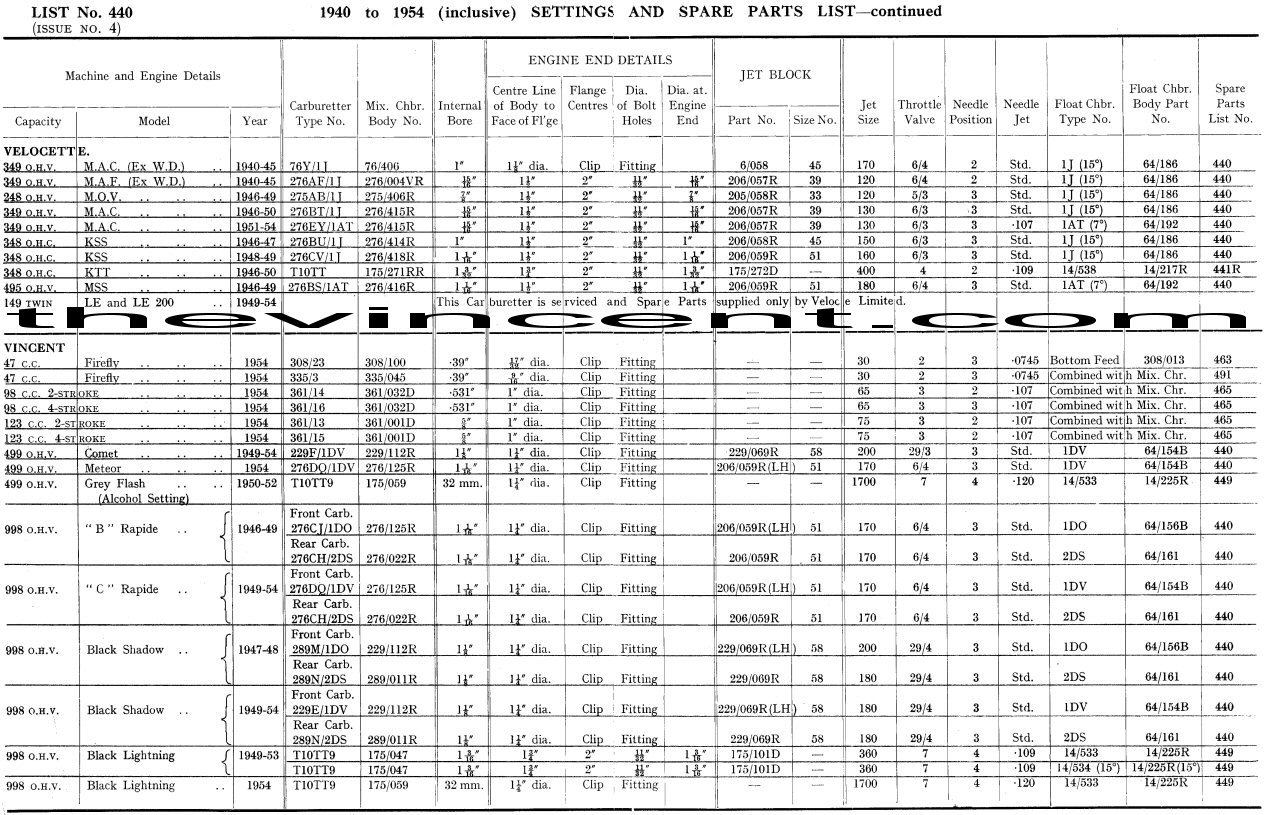

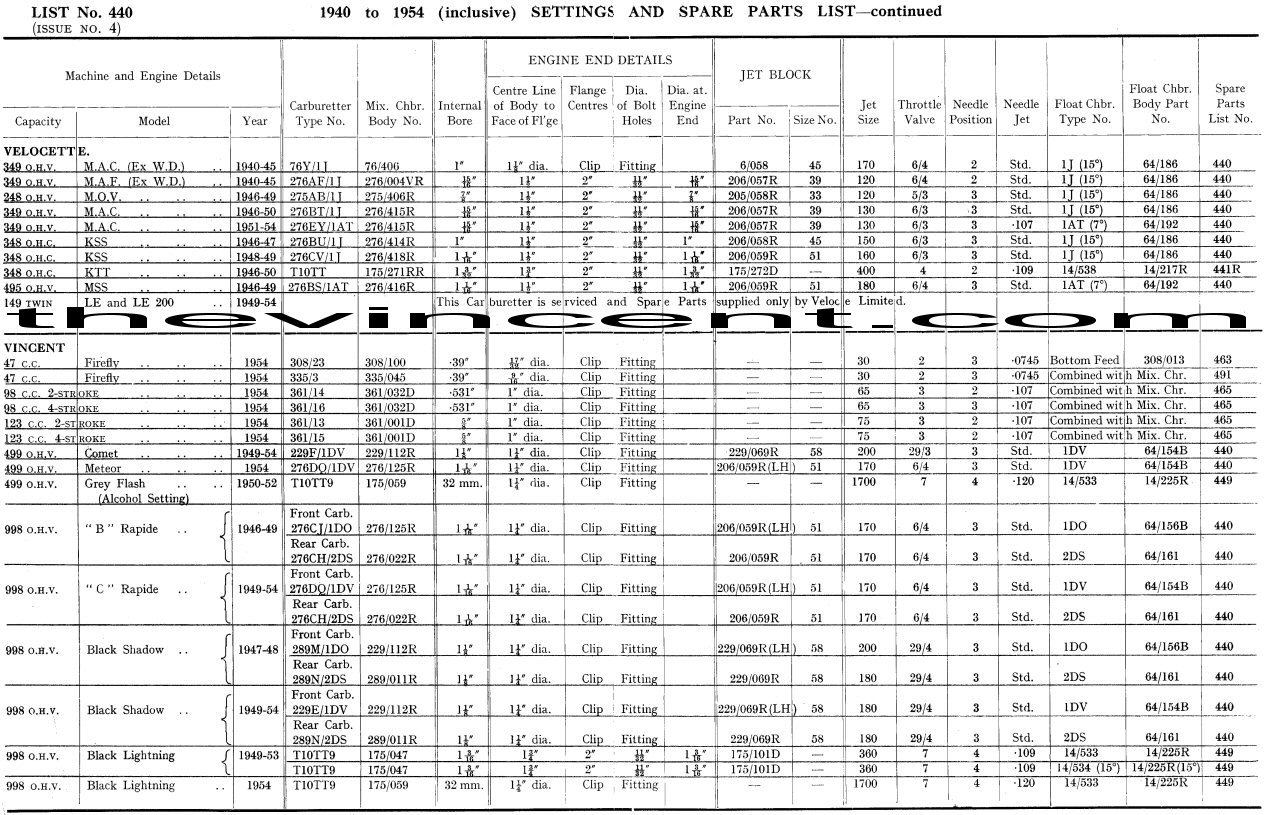

Comet 1949

- 1954

Carburetter type: 229F/1DV

Mix Chamber Body No.:229/112R

Internal Bore: 1-1/8"

Center line of body to face of

flange: 1-1/4" dia.

Flange centers: Clip

Jet block part number:

220/069R

Jet block size no.: 58

Jet size no. 200

Throttle Valve: 29/3

Needle position: 3

Needle Jet: Std

Float Chamber type number:

64/154B

Spare parts list no.:

440

Doug Wood 10/4/07

"Early" Shadow carbs,

with

the adjusters on the right side were 289M/1DO.

Carburetion and mixture

adjustment

at idle: Correct

setting of

the idle / low end air screw and throttle stop eludes many

and is

quite easy. All touring British carburetors have

their

air screws built identically, i.e. where the mixture

is rich

one backs out the screw, and when it is lean one enrichens the

mixture

by screwing it further in. The general starting

off position

is approx . one and a quarter turns out from lightly seated.

One

starts and warms up after setting it so, running

the

motor for a period of but a few minutes - or rides around

the block

to normalize temperature and cylinder function, and then

returns,

and working rather quickly with the bike on it's center or

rear stand

you begin by lowering the throttle stop screws until you

acheve a

reasonable idle speed, and then screw in the air screw

slowly from

it's general setting of 1 & 1/4 turns out - going in

slowly.

Note the sound of the exhaust beat, it will begin to slow

and weaken

as the screw is turned inwards towards bottoming out.

Noting

that, you begin to screw it out listening to the beat speed

up, -

at a certain point it will be heard to reach a peak - the quickest

point

before once again beginning to slow and falter.

Stop

there and turn it back inwards and hear it pick up speed as the

screw is

turned inwards. Find the peak position where it runs

the fastest

/ hitting the hardest . Stop. Now turn it

a little

further In { about 1/16th. to an eight turn inwards and

Stop.

That's " slightly Rich from peak ", the position

and

mixture condition sought for smooth running and

easy

starting. At the finish of this entire

procedure

you will find it fairly close to this position,

but most

motors will vary a bit here to acheve sweetest

running.

Stop the motor and let her cool down. Never

prolong the

idling period as the results of this work will be

poorer, and

motor damage can result. A Warm - Not

really Hot

engine gives the best results. Use of a fan blowing

across

the motor and pipes is a good idea to lessen chances of

blueing or

overheating . After a quarter hour of

cooldown,

restart and you find the idle speed is higher than

desired.

Back off the throttle stop until it allows a more

normal idle.

Then repeat the earlier procedure once again seeking

the air

screw position which suits the new slide position.

This will

go quickly, and then try easing off the throttle

screw

just a bit more to see if it will accept a bit less

and still

give a nice reliable and steady idle. Whenever the slide

height is

altered downwards seeking a slower idle beat it's normal

that the

mixture screw can be adjusted a tiny amount to

better

the results. Once set it will seldom need but the

slightest

tweak, usually a little inward for Winter conditions and

outwards

for Summer. All this describes the proceidure on

a British

single like a Vincent Comet, and naturally working

with a

Twin will require some thought and consideration

for

the second cylinder, but the technique is

identical.

After both carbs are set to acheve equal beats, one only needs to

sync.

the slide lift off between the two.

With

some practice you will develop a keener ear and touch,

and

it will help identify which cylinder is leading

{firing

harder} by momentarily lifting off one plug lead after the

other

- listening to only a few beats{ 2 or

3 is

enough } to gauge which is lagging behind thus needing a

tiny

bit more throttle, and which neads a little backing

off.

Thus you will balance the two. Re-sync the

liftoff after

this balancing act. Another trick is to stand at the

rear behind

the bike and listen to the idle beat from the muffler -- as

with

a long slim screwdriver you slip in beneath each slides

cutaway -

and gently lift the slide a few thou whilst noting the

change in

the beat. First one and then the other. This

will reveal

which cylinder is hitting harder and which is being dragged along

doing

little work. Seeing what is needed to balance the

effort you

ease off on the stronger cylinder and bring up the weaker.

Very little

tweaking will be needed to acheve what is desired.

Mind you

- don't let the old girl get too hot, she won't

like

it, and might punish you for doing so. All of this is

really

an art if you get good at it, not

wrenching .

And is near to being a lost one. Sid Biberman

3/15/08

Amal jets

are

sized by flow rate. As an example, a 180 jet flows 180cc per minute

with

a set head of fuel. I don't know what that head is ( a tank of

kerosene

1ft (12") above the jet normalised to 21 Deg C) a nd the flow rate

is measured

in cc per minute as it was all done at the factory. No doubt it

could be

back checked by setting up a marked jet and increasing the head

until it

flows the marked amount. Phelps 12/20/07

Tuning and Jetting Guide

For

Amal Mk.1 Concentric Carbs on

Vincent

Twins, and Singles.

There are (3) major

components to

the proper setup of Amal Mk.1 Concentric carbs when used on

Vincents. These

are: 1) Carb Modifications, 2) Carb Jetting, and 3) Ignition

Timing. Each

will be covered here in great detail.

Amal Mk.1 Concentric Carb

Modifications.

New Amal Concentrics can be

purchased

today from several sources, and sometimes, they can be bought

equipped

with the jetting that you will specify. Regardless, these

carbs whether

new, or old/used need to be "blue-printed" for use on a

Vincent. I learned

the hard way that they CAN NOT be just mounted, and used. I

found data

on the proper setup of the float level. I discovered that a

restrictor

low speed orfice must be drilled out, and I discovered that

the brass fuel

feed nozzle in the bore needs to be modified (like a Norton

850' 932 carbs).

Perform all (3) of these mods!

1) Float Setting: Normally

the float

in NOT adjustable. The float's needle seat that is in the

float bowl can

be moved slightly up or down to the precise location by first

running very

hot tap water over the seat for a few minutes, and then gently

tapping

the seat in either direction to move it. Use different sized

rods, or drill

bits in a manner that won't hurt the delicate needle's seating

surface.

The proper float height is .080" measured from the top of the

float to

the top edge of the float bowl. It is important that the stock

bowl gasket

be used because of it's specific thickness. To measure for the

.080", assemble

the float, float pin, and needle into the bowl, and carefully

hold the

float pin fully down as if it was installed to correctly

position the float,

hold the float level, and upright as if it was on the bike. I

use a .080"

drill bit, and I lay it on the top edge of the bowl near the

float (opposite

end of the float from the needle), and I "eyeball" the

thickness of the

.080" drill bit, and compare how far down the float edge is

from the bowl

edge. The float drop should equal the thickness of the .080"

drill bit.

The seat will need to be heated, and moved several times to

get this adjustment

just right. If the float level is too low, the carb will

always act lean,

and if the level is too high, the carb will always act too

rich!

2) Low-Speed (Pilot) Jet

Restrictor:

The Low-Speed jet size for a Vincent is very important, and on

the later

Concentric carbs, a restrictor jet of about a #15 jet size is

installed

that limits the available low-speed jetting size. This size is

only applicable

to 500's! On the side of the carb is an angled screw for

setting the slide

height, and a horizontally mounted adjusting mixture screw.

Remove the

mixture adjusting screw, and spring, and look into the hole it

came out

of. You will see a restrictor jet with a very small hole

(.015"). This

will need to be drilled out with a .040" tiny drill bit. Great

care must

be used while doing this to not wreck the carb, or to break

off the end

of the drill bit! Now this restrictor is equivelant to a #40

low-speed

jet (larger than you will ever need). Now, the normal

low-speed (pilot)

jets can be screwed into the carb body's pre-drilled orfice

above the float

bowl. A #30 Low-speed jet is correct for most Vincent

applications. A general

rule for selecting the correct low-speed jet is that the

fastest idle speed

found by adjusting the mixture needle while idleing should be

found with

the needle out between 1 to 1 1/2 turns out (prefferably 1 1/4

turns out).

3) Brass Fuel Feed Nozzle

Modification:

The brass fuel feed nozzle visible inside the throttle bore

(the needle

goes into it also) has a round cylindrical design where it

stands about

1/4" above the bores lower edge. This is appropriate for small

displacement

motors, but for larger applications (like a Norton 850, and

Vincents) this

feed nozzle needs to be modified. When you look into the

carb's bore you

can see this feed nozzle. The complete back half (downstream)

needs to

be cut away. To do this, carefully scribe a mark along the

lower rear edge

of the feed nozzle along the body's bore surface. Mark a small

dot with

a "Sharpie" pen to orient the exact midpoint of the rear of

the feed nozzle.

Disassemble the carb to remove this feed nozzle. Carefully

mark the sides

of the feed nozzle with vertical lines for cutting away

material. You want

to use a Dremmel tool with a cut-off disc, and be very careful

to remove

exactly 1/2 of the feed nozzles exposed material (the rear

half!!). Re-assemble

the carb. The need for this is because at low engine speeds

with only slight

throttle (slide) opening, the in-rushing air will pick up fuel

from the

needle while air is rushing around the feed nozzle, rather

than the air

having to rush over the top of the feed nozzle. Untill I

discovered this

mod, I was suffering poor low end running, as well as alot of

detonation,

and heat build-up.

Jetting Guide For Amal Mk.1

Concentric

Carbs For Vincents.

As you know, not any (2)

motors,

and their operating enviroments are going to be identical.

These jetting

guidelines should either be correct for your bike, or at least

be within

one jetting change from correct. Careful observations, and

adjustments

must be made after an initial impression has been realized. I

have discovered

some things that may influence other bikes. One is the size ,

and flow

rate of your pet-cocks. These are bigger carbs, and under hard

riding,

they may need more fuel than your pet-cocks were flowing

before. I have

had great success from the late Norton style pet-cocks with

the "paddle-type"

lever. Don't get the cheaper Taiwan units. Spend the extra

money, and get

the much better British made units! Pet-cocks can definitely

affect your

main jet size!.

Jetting Specs:

1) Slide: I like the 3.0

slide for

quicker throttle response than the standard Amal 3.5 slide.

Use "hard-chromed"

slides if you can find them. The last ones I found were at

(Clubman Racing).

The "Pot-Metal" standard style slides just won't last as long,

but they

work great.

2) Needle: I use the

standard Amal

needle with (3) needle clips. I've found the middle notch to

be best for

higher elevation, and in some cases, the lower (richer) notch

might be

best. This is a very subjective setting, where you will need

to drive test

each setting to find which feels the best. This setting

affects the feel

of normal "inner-city" type acceleration (not high, or low

speed running).

3) Needle Jet: The standard

size

needle jet is a #106. I have had better success with a richer

#107 needle

jet. This adds a tiny bit of richness to the mixture at idle,

just after

idle, and everywhere along the needles taper. This increase

was very beneficial

to my Vincent as well as my Norton 850. I have found that it

is easier

for me to remove my bowls, and upsize a needle jet instead of

removing

the carbs to change a needle clip position when going from my

home at 7,000"

elevation to sea level. Often people are changing low-speed,

and sometimes

main jets to cure a mid-range jetting problem, where a change

in the needle

jet was the only cure. I've found that bikes that ran fine

decades ago

on older style fuel usually need an upsize of at least one

size for the

needle jet to react to today's newer fuels. I've found this to

also be

true for my Mikunis! What people don't tend to realize is that

the relationship

of the needle jet orfice to the needle's shank diameter is

actually another

jet size! This relationship affects the jetting from idle to

just under

full throttle.

4) Main Jet: I have found

for a

basic Rapide, or Shadow motor that a #220 jet for higher

elevation, and

a #230 jet for sea level works best. This size may need to be

adjusted

if you are running straight through muffler, velocity stacks,

hotter cams,

etc.. I use #250 jets in my 1,164 cc "Big Bore" motor with

Mk.2 cams, 10:1

compression, and a straight through muffler.

5) Low-Speed (Pilot) Jet: I

found

the #30 Low-Speed jet to be correct for a basic Rapide or

Shadow motor.

I am using a #35 jet in my "Big Bore" 1,164cc motor.

6) Float Level: The float

level

at the top edge of the float measured at the dge away from the

needle and

seat should be .080" below the top edge of the float bowl.

This has been

covered above! Jim Mosher 11/29/07 (Jim

designed and sells Concentric manifols for Vincents at

www.performanceindian.com

....seems like an OK guy. He also posted an excellent

complimentary

article in the Vincent Tech Section on Magnetos.)

I'm running

32mm

Concentrics on F10AB/1/399;

#3 slides

, Needle clips in center groove, needle jets #106, main jets

230, pilot

jets #30. With 2500 miles on a fresh engine, it starts easy,

idle is great,

will go over 100 mph (once, according to chronometric speedo,

impulsively,

with suspension and brakes not fully set up) @ 35-37 degrees

advanced timing

with a BTH magneto. 50mpg average. Plugs read rich which

is a project

currently underway to correct. Jack 9/15/07

Mixture: 1)

mark the throttle at fully closed and at fully open. Then you'll

know whether

the trouble is slide (0 - 1/4 open), needle (1/4 to 3/4), or

main jet.

Main jet affects both, but sounds as though you have a flat

spot.

2) I'm running 190 rear 180 front with no filters. The rear is

pretty good,

the front masked by oil but there are no holes in the piston, so

I think

they're

both good. Unless the K & N filters have no impact on

airflow, you

ought to be weaker than that. 3) If you can hold the

throttle

at the flat spot and lower the air lever s-l-o-w-l-y, if the

problem goes

away before it gets much worse you were too lean, if it gets

worse before

it gets much worse you were too rich.. Roy Cross

6/19/07

If the mixture

needs a little leaning out there are two easy ways.

Place a

tiny washer UNDER the needle jet - lifting it

higher

up the needle. Fit an extra fiber washer {thus two}on top

of

the float arm , one below . This will lower the float

level.

Also you can slightly rotate the spigot carb. on the manifold

stub to lower

the float level . Sid Biberman

Idle

Mixture Adjustment:

While its easier to hear and feel on a single like a

Comet

-- the air screw is slowly backed out from snugged

in by about

1 and one quarter turns . As it leaves its

seat the motor

speed will begin to tick over faster and reach a peak at that

no. of turns

approximately, each motor a little different .

Somewhere between

one full rotation and a bit past another

quarter it will

begin to drop off again , at that point stop

,

and go back in a bit . Ease off the slide

screw

to bring down the idle revs to a nice even beat ,

then repeat

the air screw dance to see if it has changed

its needs

and re-adjust slightly the same way . The rule

is

this , the highest peak you reached is

slightly too

lean to start easily -- so go back in slightly

richer

, ie . " just a bit rich off the lean peak

" .

OUT is leaning it out , IN is going richer

.

This is an art , not a science and more difficult on

a twin

due to the other cy. firing . Takes

practice and

a good ear . Do it on a warm motor , NOT

on a really

hot one as the rising heat gets the liquid

fuel to perculate

and messes up the process . Dont let her

idle too

long and get too hot . Get it done

in

as short a period as practical for you and not

being

harmful to the motor . Prolonged idling can cook the

rings

and piston . On a twin you can lever up

on each

slide in turn with a spoke and tell from the beat which is

hitting harder

, then back off a tiny bit on that one and raise the

other

slide till they sound the same at the

tail pipe

. Good Luck . Sid .

If the float is

not distorted / crushed or full of fluid, and if the

needle

is correct pattern and not had its slot

altered then

the level should be correct or nearly so .

That

is if the bowl itself is the correct one. If

there is

a reason to suspect the mixture is rich or

lean then

this can be acertained by raising or lowering

the float

bowl by placing an extra washer on top /or below to effect

a height

change. For a fast check just rotate the

entire carburetor

around its stub fitting to lift or lower the contents

within.

Sid (8/8/06)

There is a quick way to check float

levels check to do this

without removing

the float bowls. Check and adjust the level as normal; then

modify a spare

drain plug to accept a clear flexi hose - something along the

lines of

the windscreen washer tubing, only gasoline resistant. Then it's

just a

question of fitting the modified plug and raising the tube to

above the

fuel level in the bowl. The fuel should find a certain level.

You can either

scribe a mark on the bowl or measure accurately down from the

gasket face

and record in your service book. Granted the centre carb isn't

the easiest

to check but with a touch of trial and error... If you modify

three plugs

and fit simultaneously, you can use longer hoses and compare

both levels.

Next time you think the levels are out you can at least check

both without

disturbing the carb settings. marc 8/8/06

Yes, theAmal 276/289 jet

blocks are handed, there

are two things different, one is the smallest hole on the edge

adjacent

to a larger air hole, the other difference is more obvious:

there is a

scallop out of the top to allow the idle screw to pass through.

I reckon

if you got the idle screws in you got the jet blocks in the

right bodies.

I have just tried swapping some handed jet blocks in a pair of

289's and

can confirm you will not get the screw in if they are the wrong

hand!

The 276's are handed, I think the early twins had nearly

identical 276's

so that the pilot air bleed screws were on the same side.

But the

later ones had them on the opposite sides.

Roger Sparks

4/25/06

Amal Repair

Work

AKA Lund Machine Compamy has

gone

out of business (retired) and sold to:

Andy Harden of AMAL SLEEVE Co.

http://www.amalsleeve.com/

800 295-2915

21502 99th Avenue S.E.

Snohomish, Washington

98296

USA

Concentrics:

If any one is using or wants to use these carbs, here is the

setup for

930's (30mm). This gives 1st kick starts and perfect throttle

response,

with text book plug readings (Champion #120). These are

the late

model Concentric w/#25 pilot jets built in. Starting from the

top: #622-122

throttle needle in lowest position; #3 throttle valve (slide);

#106 needle

jet (use the one with the cross hole in it; #180 main jet. set

the pilot

air screw around 1 turn open, then adjust to your bike's

requirement. Set

the throttle stop so there is a 1/16" gap at the bottom of the

slide and

adjust to your bike when warm. John Ulver 4/4/05

Mikuni heaven:

http://www.sudco.com/

Mikuni:

For VM 34's on a standard Vincent

3 1/2 slide

159Q5 needle jet

6FJ6 needle

210 main jet

30 pilot jet

#2 air jet

Needle in middle position

float arms measure 22-24 mm from casting

ridge

Robert Watson

Slides:

A couple of weeks ago at the Urshel emporium Mike showed me an

original

289 slide that he had sleeved several years ago in England to fit

a bored

out body. It was superbly done. Does anyone know who might have

done or

is doing this work? The reason I ask is that the slides that I

have had

made for bored out bodies become sloppy after a few thousand

miles. We

suspect that this is due to them being machined out of a single

stainless

blank and there is a tendency for the lower ends to contract

towards each

other facilitated by the two wide slits up the sides.

We did a little experiment. We measured the

diameter

at the top and bottom of an original slide (virtually

unworn), the

sleeved slide in question and my stainless machined slide with

three thousand

miles on it. In the case of the original and the sleeved slide

the diameter

at the lower point, just above the cutaway, was actually

slightly larger

than at the top by about 2-3 thou. In the case of the stainless

slide it

was smaller by 4 thou.

Both the original and sleeved slide were of

brass,

(in the latter case we don't know what the sleeve material was).

Could

it be that Amal deliberately built into the design a slight

differential

in diameter so that the lower slide edges were always under

slight tension

against the body ensuring a good seal?

Experience has also showed us that when you

mechanically

widen the diameter, by carefully prizing the lower edges of a

slide apart

a little, the brass will retain this new attitude allowing you

to get several

thousand more miles out of it . However a stainless slide will

return within

a short while (days) to its original attitude as if it has a

"memory",

this in spite of the fact that the stainless slide is at least

10 thou

wider in wall diameter. Tim

Baldric 4/3/03

CV Carburators:

Everybody who experiments has concentrated on high efficiency

carbs,

like the TT/GP's, flatslide Keihins or Mikuni's, or round slide

Mikuni's--or

even Dellorto's. The bad rap on CV carbs is the flow is less

than

optimum because of the butterfly valve in the airstream. The

benefit

is that since the slide opening is responsive to vacuum from the

intake,

the mixture should always be perfect. It's a "demand"

system.

Even with shelves full of high-performance carbs, I've thought

seriously

of trying CV carbs on a Vincent engine. Despite

appellations

like "the Beast," your post-war engine is in a relatively mild state

of

tune, and requires neither the lightning response nor the

enhanced

flow characteristics of the best of the competition

carburetors.

If your Vin is in a relatively standard state of tune and

displacement,

I wouldn't recommend a bit over 34mm bore, even with a CV carb--and

maybe

not even that large.

For example, if you have done any cleanup in the ports and have

9-9.5:1

CR and MkII cams, up to 34mm could be OK (given the poor top-end

airflow

characteristics). But the lovely thing about the CV delivery

is that

you will find a smooth operation no matter the speed range or

demand you

place on the carbs. John Caraway 12/14/01

Synchronizing Carbs:

The one thing to remember is that with the one cylinder

inoperative , with

the removal of the plug, and maybe the plug hole open. Is that the

back

pressures will not be functioning as normal, and you will NOT get

the setting

correct. If you want to find out more, try setting the carbs

up with

vacuum gauges, and you will find that when you adjust the throttle

stop

on one carb, the gauge on the other cylinder moves. I would say

it`s almost

impossible to get the carbs synchronised , by any other means than

with

gauges. Trevor 04/24/01

Regarding where to sleeve

carbs in the

USA:

Mike Gaylord does Mk l Concentrics at 360 456-1425; Walt

Lund machine

does Type 6's and Monoblocs at 520 790-9875. Carl

Hungness

04/19/01

Many

leaky float problems on the

27's &

29's are caused by poor fuel shutoffs and short side stands.

Remove

the fuel lines from the shutoffs and there should be no, I repeat

no fuel

dripping. The standard sidestands lean the Vincent over too

far,

on the left stand the rear carb. will drip until the the fuel

level drains

off from the float chamber through the bleed hole in the jet

block,

because the level in the float just got raised above the hole, and

then

out on to the back of the engine. On the right stand it's the same

for

the front carb., except that it drips on to the primary case.

If the fuel taps aren't dripping , then dip

each

needle in Brasso and give each seat a rub. Then extend each side

stand

3" so that your bike will stand up straighter.To prove if it's

the stand's

fault, the carbs.shouldn't drip when the machine is on the rear

stand.

To go the extra mile I machined an "O" ring

groove

in the needle of the front carb. right where it seats, after

installing

the "O"ring I then ground it flush with the tapered needle.

The rear needle, I shortened, and drilled

it so

that a Mikuni float needle could be snapped on to the end of it.

This then

required boring the old seat out and making and pressing in a

seat that

matches the new needle. They still drip! So! One minute before

you plan

on stopping, turn off the fuel, this will lower the fuel level

enough to

stop the dripping. Thats what I do. Dan Smith

03/09/01

I bought a K&N

"high flow" air filter, was

told by my

friend, Dynojet and K&N that the reason for my performance

accelerating

was because of the weather. Thanks to my wife for having the same

bike,

just stock and running better, they were wrong and many of you on

this

forum were right. I broke down this week and moved the

needle to

3.5, which did little and finally the 4th notch on the Dynojet

needle.

The bike not only is responsive but very smooth, no on/off

rocking, no

lag in thinking about accelerating, etc.

Many of us bought the K&N a month or

two ago

and I'm sure someone, other than just me, will have the same

problem. The

forum discussed how a "higher flowing" filter would require

adjusting the

carb. Take note The K&N may require a needle adjustment, but

the adjustment

may make your bike the best it's ever been. I still can't

believe they

market this air filter as "high flow" but insist carb changes

are not necessary.

Pascal 02/15/01

Float needles

as originally fitted to Amal Monoblocks and Concentrics were solid

one

piece nylon needles. In response to reports of dripping and

seepage

past the needle, newer up-graded needles( the Viton rubber

tipped

version) were later offered as an extra cost option. About the same

time

Amal described a modification to both tapered needle and

needle jet

holder which quite transformed the running of the Concentric. The

long

needle now had 3 circles about its upper end and the jet carrier was

longer

in its lower portion. A reminder was made concerning the

little

brass hood situated in the base of the choke - that the 4 stroke

part was

cut off straight across its top while the 2 stroke version was cut

off

across its top at a steep angle. Many complaints of mixed

assembly

between body type components resulting in poor tunning have been

received

at Amal. The motorcycles ran poorly and were a beast to start

!

I found this mix-up on a BSA 441 that was a pig to start.

After correcting

the mismatched pieces, starting became far easier, low speed

running

far improved, and roll-on power increased. If your motorcycle runs

like

a pig have a look inside its carburetor ! S.M. Biberman

Beware of Vitron tipped

carburator needles if you are running on unleaded

petrol.

I bought a new Monobloc carb for my Comet and couldn't understand

why the

needle stuck in the closed position after every ride. A friend

then

advised me that unleaded petrol reacts on the vitron. Since

changing

back to an old type standard needle I have had no more trouble. D.J.

Peters

01/18/01

I think what you are referring to is actually Viton

without

the r. I also suspect that the problem with the carburator

needle sticking is more likely that it is a

mechanical wedge

into seat than the rubber sticking. Dan Smith cut o-ring

grooves

in his type 29 remote float needles and put o-rings in them and then

ground

them to the taper leaving them just a 1/2 thou proud and they stuck

shut

every time. In frustration he ground them flush and ta-da,

they worked

perfectly. One of the only rapides running original carbs that

don't leak when you leave the taps on and put it on the side

stand!!

Robert Watson 01/18/01

I made a pair of flange-to-flange

adapters for MK I's.

Here's how

I did it.

First I polished the necked-down portion of

a

pair of standard adapters. Then I made a pair of flanges

that were

a few thousands undersize. With the adapters temporarily

mounted

to the engine, I put some alignment marks on the adapters and

the flanges

so I could install the flanges in the proper orientation.

Next step...put the adapters in the

refrigerator's

freezer compartment and the flanges in the oven at about 350-400

degrees

F. Place the hot flange on a flat surface (such as a

smooth block

of wood) and plunge the cold adapter into it. If it won't

fit (which

mine didn't on the first two attempts) polish the necked-down

portion of the adapters a little more.

Repeat the heating, freezing, and plunging

steps

until you can get the adapter to bottom out in the flange.

Mine work perfectly--a complete seal was

accomplished.

Someone with a milling machine can make the holes for you to the

kind of

precision required. Just have them drill the two mounting

holes and

bore the center intake passageway. You could also get them

to mill

a good flat surface on one side. Afterwards you can cut

them out

with a hacksaw and file the edges to match the flanges on your

MK I's.

A few VERY careful strokes with a flat file will assure a good

mating surface

if the adapter went slightly past the milled surface.

Without going out to the shop to measure

the thickness,

I would guess mine are about 1/2" thick--it was just

a scrap of aluminum I had on

hand.

"Jay" 9/14/00

Mikuni Modification by Bill

Easter

6/28/00 A number of people, Glenn Shriver and

others,

are using Mikuni VM carburettors on their Vincents and some would

like

to use cable start (choke) on the smaller 28 mm instead of the lever

mounted

on the carb. Here is a suggested modification to the cable start

parts

which I have not tried yet. The problem is that the vertical

space

for the piston and spring in the 28 mm and smaller carb. is about

0.225"

less than in the 30 mm and larger carbs. The diameters and

thread

sizes of the parts are the same. I suggest boring the bottom

(threaded

end) of the threaded cable start fitting 0.225" deeper so that the

spring

can go into it this much further and shorten the cable adjuster by

0.225".

Turn the full length of the top of the piston (slight smaller

diameter

of the piston and portion with slot and hole for cable nipple) down

to

0.260" from 0.293" so that it will go into the threaded

fitting.

This will also require that the cable end nipple be reduced in

length and

possibly shaped/radiused at the ends.

Hylomar

for leaking carb washers.

As I happened to have some of this already, and the data sheet

states it's

completely gasoline-proof, I decided to try it. I soaked new

fiber

washers in Hylomar, coating them completely, and also applied it

to the

threads of the various fuel fittings. On reinstalling

everything,

it seems to have done the trick - no visible leakage! I

haven't given

the system an acid test yet by going for a long ride, but it's way

more

gasoline-tight than it was before. Also, Hylomar is neat

stuff -

it's non-setting, so you can smear it about pretty freely and then

wipe

it off anywhere visible when you're done.

5/22/00 VOC-Jtan

Time for a few comments from

the

Western Canadian contingent about carbs,

piston

holes and the interconnections

in life!!

I have run original Shadow carbs on the

Woolly

and when I went up to 9.4:1 I also went to 34 mm flat slide

Mikunis.

The carbs were new and jetted very rich, like 25 MPG rich.

After

many tries and 3 seized pistons I got the jetting really close

and no more

holes. I am now running HD electronic ignition and with no

suitable timing

device installed have set my timing by ear- like advance till

you detonate

and the just back a bit. Good enough to run mid 7's at

Ramsey and

also give a real good thrash around the Island. Many

times

I hear people with pistons holed who immediately blame the

pistons but

I feel the holed pistons are the result of the problem and not

the cause.

I must agree with Sid, for who am I to disagree, that you need

to look

at mixture, ignition advance, and fuel supply problems

long before

you blame a piston.

I know of one such piston being blamed and

yet

running over 40 degrees advance! My experience says if you

are getting

more that 55-60 MPG on a nice 65 MPH cruise for a full tank then

you are

probably too lean. Don't assume when something breaks that

it is

a problem all by itself, life doesn't work that way.

By the way I recall some suggestions about

Mk

2 concentrics and jetting some time ago. If any one has

them could

they send them to me. It seems a Twin recently arrived here is

running

rather rich and has a brand new set of Spanish Mk 2s.

And a note for Nick Cleary. I'm not

promoting

and I know some may disagree but, making reference to the above,

Danny

Smith ran Kemp's pistons on his 30,000 miles plus travels to the

tip of

South America and then up to the

Yukon and they sre still just fine. Shadow

type

29's, Mag ignition, and the addition of chrome top rings.

If you

have the confidence that you are going to keep your motor

together and

not need to disturb them, put in good chrome rings, and hone the

bores

to the clearance recommended by the piston guys to the finish

recommended

by the ring guys. With a good seal, no blow by, no oil

leaks, no

fancy breather (another of those blame the breather

when your leaky rings are pressurising the

cases

causing the leaks) and you should get a sweet running

motor.

Robert 4/04/00

Holed Pistons:

Usually it is a mixture setting and/or restricted fuel flow

promoting

a severely leathal condition . Also high on the list of causes

would be

excess ignition advance . The flow fault is often as simple

as a

clogged filler cap vent hole or fouled filter screens on

the

fuel taps, or even not always opening both taps at sustained

and

elevated speeds..

The early original cork taps are always

suspect

at providing sufficient flow for speeds above 60 -70

MPH

and never for top speed runs . Larger bore lever

taps and opening

out larger that cap vent is tops on the list for serious Vincent

riders

as would be closely setting ones ignition timing .

Incorrect

jet sizes, sticky floats, and inlet manifold air leakage at the

male to

female joint ( particularly that last one) are very common on

older Vincents.

S.M. Biberman

Petcocks

Sid,

That reminds me of a time I was riding

home on my Vin, one afternoon, in fast traffic, on a single lane

in each

direction road. I was running on the left side tap and using the

right

side tap as reserve. As luck would have it, she started to run

dry going

over a fairly long bridge. So I pulled out the right tap for

reserve. And

I mean, I pulled it out! It seems that the stop screw had backed

out on

me and was no longer doing its job.

So here I was, going up a grade, on a

bridge,

with no place to pull over, with my petcock in my throttle hand,

as I watched

my reserve fuel poring out on my right boot and exhaust pipe, to

the sound

of my carburettors backfiring from lack of fuel. To prove

the old

bromide about God looking out for fools, I was able to put the

the cork

carrier back in the petcock on just the second try, (I was

wearing winter

weight gloves at the time), and still had enough

fuel to make it over the bridge and to pull

over

and empty my boot of the excess fuel it was now holding.

So to my fellow Vincent owners, don't

try

to top this. Please check those petcocks and think about an

upgrade. (

I did, and I also put a little extra $ in the plate, the next

Sunday).

Ken Smith ( Phil. Pa. USA )

return to thevincent.com

Vincent

Technical Sections: -Serial

Numbers/Production-

Photo Gallery of Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments

- Transmission

- Clutch -

Magneto

- Tank/Seat - Suspension

-

Tools - Norvin

-

Electrics-

Carburetors

- Misc - Links

-Vincent

Parts/Services

Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

Vincent

Technical Sections: -Serial

Numbers/Production-

Photo Gallery of Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments

- Transmission

- Clutch -

Magneto

- Tank/Seat - Suspension

-

Tools - Norvin

-

Electrics-

Carburetors

- Misc - Links

-Vincent

Parts/Services

Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers