Vincent

Technical Sections: -Serial

Numbers/Production- Photo Gallery of

Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments -

Transmission -

Clutch - Magneto - Tank/Seat - Suspension

- Tools - Norvin -

Electrics-

Carburetors - Misc - Links -Vincent

Parts/Services Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

New Technical Section (just being developed ..these photos are hard to

work with.. I give up for now..)

NORVIN (a Vincent engine mounted in a Norton motorcycle

frame)

Last Edit: February 23, 2018

Engine Mounting: Some Norvins, even with

complete frames, have been built with substantial upper engine

mounts. I think that this is a bit of an over kill, but hey, it

probably doesn't do any harm. A sturdy head steady is mandatory

though. The Norvin with the lower frame rails removed is still

around. Known as the Italian Norvin even though it was built in

England and then exported to Australia for the '83 International

rally before going to Italy. Whilst removng the lower frame rails

does allow you to move the engine/gearbox around, I  don't see any further point

in it. One may as well then fit the steering head to the top of the

cylinder heads and then, oh, bolt the swinging arm to the back of

the gearbox and remove the rest of the frame and oh gosh, we have a

standard Vincent. Cutting up a Manx frame will

don't see any further point

in it. One may as well then fit the steering head to the top of the

cylinder heads and then, oh, bolt the swinging arm to the back of

the gearbox and remove the rest of the frame and oh gosh, we have a

standard Vincent. Cutting up a Manx frame will

probably result in you being paid a visit by the Norton Club

linching crew. It's equivilant to cutting the gearbox off a

Vincent engine. Besides there is something visually appealing

about the Vincent unit being "Framed" by the Norton

Featherbed. Phelps 6/9/07

I built a Norvin a few years

ago and found it uncomfortable and top heavy. The engine

necessarily has to sit high in the frame as you can't get it to sit

between the lower frame rails (as the manx engine does), so raising

the C of G. The wideline frame makes an uncomfortable riding

position and makes kickstarting difficult. I eventually sold it as i

found i was not using it. With a standard twin and single in the

garage alongside the norvin, i always chose one of the other bikes

when going for a ride. The Norvin looked beautiful but I found it

not very practical.

If I had the chance again I would build an Egli or probably a

Vincati. Much more user friendly for an octogenarian, and there is

lots of information out there with the ozzy, and not least, Big

Sids, Vincatis. Les Craggs 5/14/07

Check out the way Dave Dresda does his featherbed for Vincent - the bottom

rails are spread to get the engine to sit down low - a nice

compromise and the rear lug isnt chopped ! . And of course, use the

two piece cylinder studs so you can pull the heads off with the

engine in the frame. Terry Prince has some really nice Stainless

ones.

http://www.dresda.co.uk/bikes2.asp?CAR=9

Norvin Frame:

If

I were to build a Norvin I would cut the tubes connecting the left

and right frame loop, spread it a bit apart and start from there.The

aim is to get the engine as low as possible as it is so heavy. Even

ín the original Egli the engine sits a bit high - on my second frame

I lowered it 1,5 inches without any harm or ground clearance issues

and was rewarded by a much nicer ride and better handling bike.

Donīt know about Vincatis but all the pictures I saw of them seem to

have the engine on the high side as well. When building race Nortons

etc I always try to get the crank below the wheel hubs - as low as

possible and as much forward in the frame as well. The little blue

Norton got 78 kg on the front wheel and 62 on the back - with rider

this gets an almost even load on both wheels and is noticable when

comparing the feeling to an ordinary Atlas. Next plan is a Dunstall

frame where the front wheel almost rubs the fins of the motor when

fork is compressed....

I would not cut the original Manx frame however - sell it and

have a wider featherbed made for that money -might probably leave

you with some extra

cash in hand and a better suiting frame. Hartmut

5/15/07

General Comments:

My Egli, Norvin and C Shadow all share the same 56 inch wheelbase,

give or take for rear wheel adjustments (a Ducati bevel has a 61

inch wheelbase for comparison). The Egli and the Shadow both

have the crankshaft 24 inches behind the front wheel, the Norvin

26.5. The limiting factor on the forward placement of the Norvin

engine was the front exhaust pipe, which still required 'massaging'

to clear the front down tube (with chopped cases I need the full

frame). The Norvin crank is also a couple inches further back than

standard Norton, as I found out when I tried to use a Norton primary

cover. I did make the Norvin gas tank shorter than the Egli's

so I can sit further forward. I thought the Norvin was going

to be heavy but it's coming out OK, the AMC box must save some

weight.

The Egli and Norvin both have the same length Ceriani RR forks

and tires, both sit in the same location in the trees so the

steering heads are appx. the same height.

Paul Zell 5/16/07

General Comments:

I lifted the swingarm shaft by 4mm lowered and tilted the engine

(not much) and used a smaller rear wheel ( 18"instead of 19"). When

upgrading the front brake I had to use a wider/higher tire as the

19"Speedmaster couldnīt handle the braking forces, washed out on

many bends and was used up within 500 km. So the front fork was

shortened a bit as well. No negative feedback from the slightly

different swingarm angle but I donīt ride the thing anymore as the

Norton is so much lighter, does the same topspeed and is more fun

when it gets twisty. Hartmut 5/15/07

General: Well ,

having built both an Egli and a Norvin recently: I cannot

think of a single drawback of the Egli style frame in comparison to

the featherbed. The featherbed has compromises in engine

location, carb and exhaust clearance, separate oil tank...

There are however arguments to be made for using what you have on

hand and building something nostalgic and eye pleasing. If it

weren't for this we'd all be riding new bikes, no?

I had chopped cases which made sense for a featherbed since the

standard Vin twin swing arm pivot is gone, the featherbed

obviously has one and also the AMC gearbox is right there already

mounted. With removable cylinder studs the heads and barrels

come off in the frame. A chopped engine also sites a bit

lower in a featherbed than a complete. I thought long and

hard about spreading the lower rails but in the end did not

because my crankshaft sits just about lever with the AMC gearbox

mainshaft already.

With the swing arm pivot on a Vin twin (standard chassis or Egli)

incorporated in the design the height of the engine directly

determines the angle of the swing arm. My Egli engine looks

high but with long travel suspension (relative to other vintage

iron) the swing arm is level when I am on the bike. There is

no way to lower the engine without having the swing arm at a

unfavorable angle, tilting the front of the engine down

substantially or using 16" wheels. Paul Zell 5/16/07

Norvin Brakes:

(4LS front wheel between Norton Commando forks) I`m working

with a front hub from a water buffalo (Suzuki GT750) and I`ve

milled about as much from the brake plates as possible without

removing the speedo drive in order to get it between the

forks...still don't have the room between my forklegs. There were

different sized Norton steering crowns and I'm wondering if

I`ve got the narrowest one ? Anyone know what the different sizes

& models were? Or is this the best reason every for custom

aluminium steering crowns ? Marc Beaudry 4/17/03

Norton Forks:

I always deal with the Norvil Motorcyle Company if I want Norton

parts. Les Emery, the boss is a mine of

information and will give you any information you want.

There are certainly two widths of fork yokes listed in their free

catalogue - 7inch and 7 3/8 inch centres. Contact

Les at :+44 (0)1543 278008 or e-mail at

mail@norvilmotorcycle.co.uk. Derek Peters

4/17/03

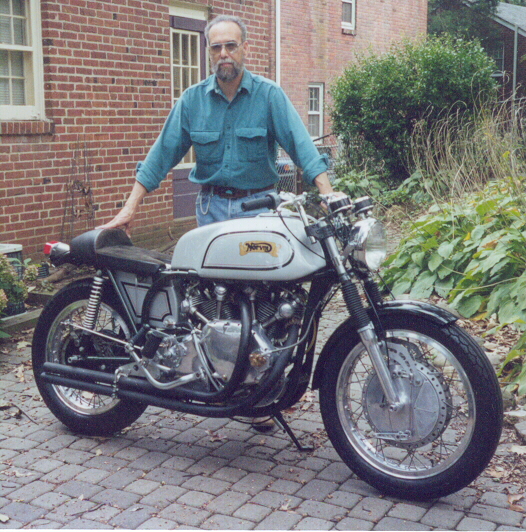

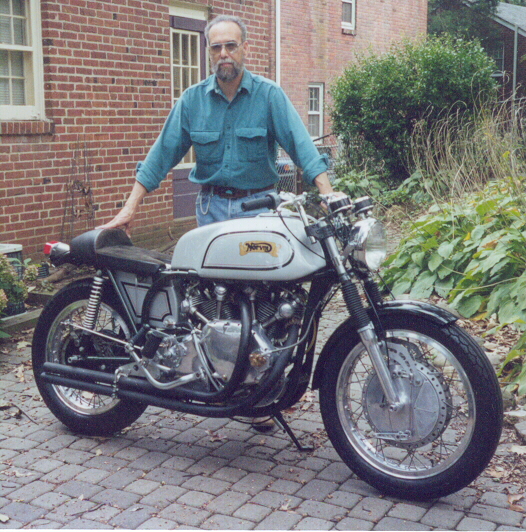

Build details of Ken

Phelp's Norvin: I have built both my Norvins (the other is a

racer) and have been using my road bike as a daily ride for well

over twenty years. The bike as it is in the photo runs a

250mm 4LS Magnesium Fontana front brake, and a Laverda 2LS rear

brake. Norton forks are really early sliders with late internals.

1956 Norton Dominator frame with Koni shock absorbers. The fuel

tank is of unknown origin, possibly Dresda and the seat is my own

aluminium alloy ducktail and base. Black Shadow speedo and Triumph

headlight. The engine has been detuned of late to cope

with the crudy petrol on offer but still runs 36mm Dellorto pumper

carbys' on matching long manifolds and ports. Std valves are

opened by Lightning cams onto 8.2:1 pistons with ignition by the

standard Lucas magneto. The exhaust is my own fabrication using

slightly larger diameter thicker wall pipe into a straight through

resonator megaphone 'Muffler'. The rest (oil tank, foot controls,

bracketry, piping etc.) are of my own construction.

My Norvin has a Yamaha 270(?) mm 4LS front brake in 7" (narrow)

Roadholders, not Commando forks, but the sliders are basically the

same. However, you need to measure the center to center

distance of your fork tubes, then you will know if you have the

narrow or wider triple clamps and what your options are. If

you also look at the bottoms of your sliders you will see that there

is an inward projecting shoulder on each one. You can mill a

fair bit off each of those to get more clearance. I assume you

have removed the original brake plate retaining boss on the backing

plate side. David Stein 3/26/03

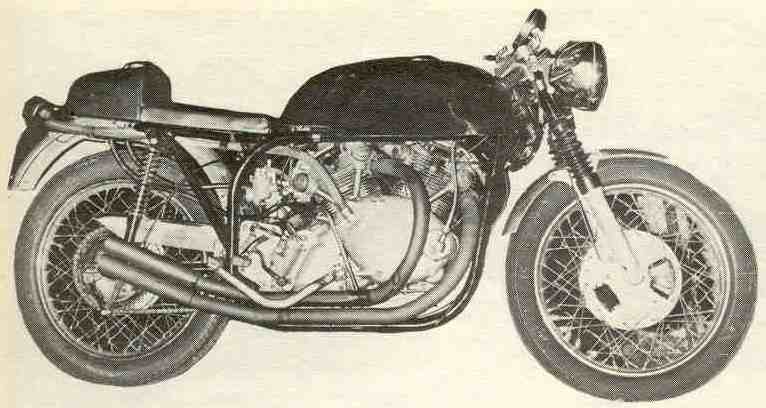

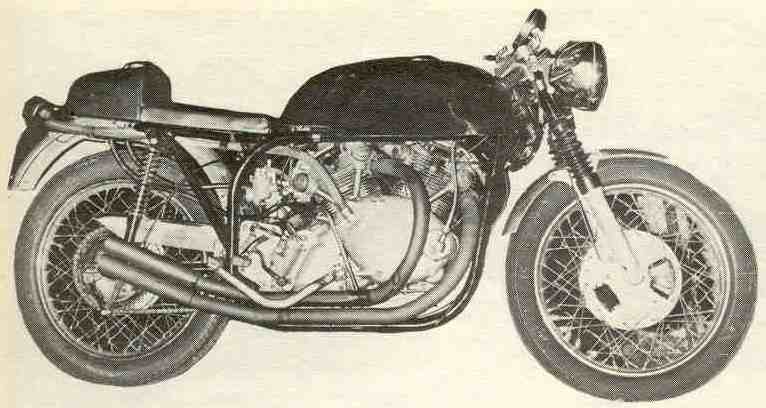

Phelps Norvin:

The bike as it is in the photo runs a 250mm 4LS Magnesium Fontana

front brake, and a Laverda 2LS rear brake. Norton forks are really

early sliders with late internals. 1956 Norton Dominator frame with

Koni shock absorbers. The fuel tank is of unknown origin, possibly

Dresda and the seat is my own aluminium alloy ducktail and base.

Black Shadow speedo and Triumph headlight. The engine

has been detuned of late to cope with the crudy petrol on offer but

still runs 36mm Dellorto carbys' on matching long manifolds and

ports. Std valves are opened by Lightning cams onto 8.2:1 pistons

with ignition by the standard Lucas magneto. The exhaust is my own

fabrication using slightly larger diameter thicker wall pipe into a

straight through resonator megaphone 'Muffler'. The rest; oil tank,

foot controls, bracketry, piping etc. are of my own

construction. Ken Phelps 3/27/03

Norvin Notes:

www.voc.com.uk/ogri

has the photo build history of the bike I am effectively copying,

and notes relating to parts and services suppliers (but please note

that Asa Moyce of Bartel (Northern Ireland) no longer makes the

combined oil / fuel tanks, but still makes fuel-only Manx etc.

tanks. Instead, enquirers can be referred to TAB Engineering

(Mr TA Baker of Aberystwyth, West Wales, UK) on tel. +44 1974

821469.

Other items to be borne in mind for Norvin builders using an

unchopped Vin Twin engine: if using a Grimeca rear hub, it's

necessary to do transpose the relative positions of the torque arm

anchor and brake cable abutment points for left-hand operation,

and of course to weld a corresponding torque arm anchor tab on the

left hand side of your box-section swingarm. These Grimeca

cush-drive rear hubs come poly coated in black, so I have had all

4 exterior hub component surfaces garnet- then bead-blasted bare

to take a nice polish on the bare alloy. I've also had the

alloy wheel sprocket turned down for a 1/4 in chain.

Also necessary on frame: cut and weld to half thickness the

left-hand bottom tube where it blends with the L/H gusset plate,

and cut back the gusset plate itself to accommodate the L/H

crankcase lug co-axially with the S/A spindle pivot point.

For this you must also mill a 1/4 slot roughly central through the

lug on a horizontal miller, but not so deep as to break through

into the chaincase. Also, the chaincase part of the casting

has a curious circular projection underneath which must be ground

off; in fact you should grind a little further back the metal in

that area (i.e. chaincase bottom rear) for best bedding with

bottom rail / gusset plate junction..

Photo of my own swingarm attached herewith. Currently I'm

opening out the slots and blocks and making new shouldered sleeves

for the wheel spindle, as my Grimeca centre is 17mm, but Pete

Lovell who makes the Norvin swingarms built mine for a smaller

spindle. Too bad it was already polished and bright nickel

plated, but I'll know next time.

It should be remembered that some Norvin builders dispense with

the featherbed frame's bottom tubes entirely (viz. the Itlian

Norvin from MPH magazines passim). They don't bear any load

anyway if the head-steadies are effective, and could therefore

retain the standard Vincent crank balance factor. It could

be argued that this latter approach allows the engine to be

dropped slightly lower at the front for lower C/G and to enhance

the handling, but the Ogri Norvin hadled superbly by all

accounts. With bottom tubes in situ, the Ogri engine was as

low as it could be consistent with box-spanner access to the sump

drain plug.

It would be nice to enquire whether the current owner of the Ogri

Vincent (last heard of he was a Swiss gentleman) is willing to

share his experiences with the rest of us. Phil Blakeley

2/1/03

Return to: Home Page of thevincent.com

don't see any further point

in it. One may as well then fit the steering head to the top of the

cylinder heads and then, oh, bolt the swinging arm to the back of

the gearbox and remove the rest of the frame and oh gosh, we have a

standard Vincent. Cutting up a Manx frame will

don't see any further point

in it. One may as well then fit the steering head to the top of the

cylinder heads and then, oh, bolt the swinging arm to the back of

the gearbox and remove the rest of the frame and oh gosh, we have a

standard Vincent. Cutting up a Manx frame will