Vincent

Technical

Sections: -Serial

Numbers/Production-

Photo Gallery of Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments - Transmission

- Clutch - Magneto

- Tank/Seat - Suspension

-

Tools - Norvin

-

Electrics-

Carburetors

- Misc - Links

-Vincent

Parts/Services Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

VINCENT GAS

TANKS

AND SEATS (see

paint section too..)

(see

paint section too..)

A Petrol Tank

Cleaning Method : Using a 1600 lb.

engine driven high pressure washer, and a home made 30 gal. auxiliary

source tank, the job is made easy. Fill the tank with water made

into a solution with common baby powder or pumice, whichever you have

on hand. Modify the pressure washer wand end, bending it into a

90o angle, and cover the tank with a protective wrap to prevent any

mishaps with the paint. With the gas cap and petcocks removed,

insert the 90o wand into the gas cap cavity. Engine running,

pressure up, sporadically trigger the wand in all directions for no

more than three or four minutes. This is usually enough to remove

all rust to a shiny metal surface.

Cleaning the tank of the grit goes like this:

Flush a couple of times with water.

Let the tank dry. You can assist drying by using a shop vac on

"blow" in the gas cap hole.

After the tank is thoroughly dry use your shop air compressor at 125

lbs. pressure. Blow in the gas cap and petcock holes.

When you see no more "white cloud" exiting the tank, the job is

finished.

You can then use the quality tank liner sealant of your choice to

protect any further rusting to infinity.

The trick with tank liner sealants is in the preparation. It only

takes about an hour to properly remove rust and seal tank. Of

course you follow the directions, and there is a cure time on all liner

sealers. It's a good idea to double that time before the tank is

put into use.

After about 10 cleanings with the wand, the pressure tip will have to

be replaced. The nozzle orifices erode rapidly. (

Max Lambky 3/16/11)

Most, if not all restorations,

involve the

seat. The best restorations are accomplished by rebuilding

an original. Often when rebuilding an original seat the only

items that will be retained are the rolled edge metal tool tray slide,

the A frame containing the front seat tab mount, the two rear support

tabs, the delta concave rear fender clearance shield, the two flat bar

stiffener straps, and the horizontal loop tubing support.

In every case when restoring one of these old bikes, the ply board

base, the foam and the cover, will have to be replaced if you're

looking for a quality end product. Sixty year old foam hardens

and loses it's elasticity, the ply board laminations are usually

separated and weak, and in the case of the Naugahide cover, where the

backing was cotton cloth, the cotton has lost it's youthful

vigor. The cover, the ply board, and the foam are all readily

available. If the ply board on your old seat hasn't deteriorate

too badly, you can easily use it for a template to cut a new one.

I make sure when I buy it, that I am buying waterproof marine ply

board, instead of the commonplace interior/exterior that's bought at

the local hardware store. If you cut your own ply board base,

make sure you sand the edges. It's a good idea to sand a 1/8"

radius on the lower edge of the ply board base, as it will greatly

improve the longevity of the Naugahide cover.

For durability of metal parts, they can either be stripped, primered

and painted, or powder coated. On the seats that the Vincent

company had made, the metal was all painted black as well as the ply

board. The covers were attached to the ply board bottom both by

staples and by upholstery flat brads. I prefer the brads.

To me it adds a touch of class. In regard to the cover itself,

you'll probably be happier if you have a reputable upholsterer who

specializes in antique motorcycle seats, do the job, rather than using

a seat cover manufactured in India. And selection of the

Naugahide is paramount in achieving a "Class Act" seat when

finished.

It's time to talk about the woes of some of the after market

seats.

Here are some of the things I've found to be unacceptable: The front

ears too short, not allowing clearance between the seat and the rear of

the tank. Bottom A frame rear seat tabs either too close together

or too far apart, causing binding of the friction shock uprights.

Seat base made from particle board. Poorly fitting fiberglass,

delta shaped, concave, clearance shield. Poor glue

adhesive. Naugahide covering not even close to original.

Naugahide stitching not to original specs.

If you don't have a seat with your restoration, you have to work with

what you do have. If your bike by some misfortune has one of the

aforementioned after market seats, I'd approach it like this:

Ensure that the A frame bottom bracket is correct. Measure the

center distance of the four tabs on the bike's rear frame member.

Ensure that the distance is the same on the bottom A frame attaching

support of the seat at the rear. This cannot be over emphasized,

as it is very important for proper operation of the friction operated

rear seat upright supports. All friction is directed at the

friction lining, and nowhere else, i.e. seat mounting bushings.

If you're satisfied that the seat mounting points are correct in regard

to the mounting points on the bike and the rear swing arm, when

friction knobs are backed off, the shock and spring boxes are removed,

and that a free, effortless, up and down movement of the swing arm is

achieved, (for this check I hang the bike with tie down straps located

at the forks and at the rear of the fuel tank with my handy dandy

homemade A frame), you can reinstall rear swing arm spring boxes and

set the bike back on the ground.

I know it'll be hard to do, but for a nice job on the seat you'll more

than likely have to throw away the entire after market seat except for

the flat bar A frame with mounting tabs, and the foam portion of the

seat. If the delta concave splash shield on the rear of the seat

is fiberglass, the only way to get a nice job is to take that piece,

and the newly cut marine ply board to a local metal man that can form

you a piece by hand, or if your talents lie in that area, and you can

do it yourself, you'll save a buck or two. So you salvage what

you can, and undertake the above procedures where necessary. More

than likely you'll end up being a "happy camper" and proud of the end

product, which will be functional and show worthy.

Max Lambky 10-23-10

Series "A" tanks:

When

soldering

(actually silver brazing) stainless steel I had

good luck using a lower temperature silver brazing compound with

metalsmithing flux. I believe that the flux which I used was a

commercially available paste specifically for gold, silver and copper

work but it was very much like a borax paste. When the silver brazing

temperatures got too high the flux would break down and oxygen would

then reach the metals being joined not allow the silver solder to

flow. Paul Woebling 8/16/10

Gas Tank Procedures

Mounting and Preparation

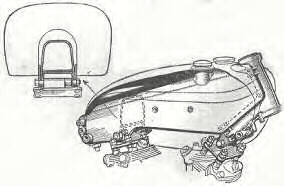

On almost all motorcycles, the

crown of the restoration is the gas tank. This is what you see

first when you walk up to a bike, as the gas tank is the primary

identification of the marque. Any blem, or something that just

doesn't look right, i.e., striping, logo badges, gas cap, and in the

case of the Vincent, of course, the Mercury Crest. Before you

bring the gas tank to a concourse state cosmetically, it's a good idea

to do some preliminaries.

First determine if the tank

you have is the tank you want. Often basket cases are a

hodgepodge of this and that Vincent parts. There were four tanks

made for Vincents, and possibly one other for prototype Indian

Vincents. The outside configurations were all the same, but the

bottom cavities provided for carburetor clearance and frame clearance

were quite different. Rapides normally had a smaller cavity in

both the B's and C's., than the Shadows in the B's and C's. The D

tank won't fit on the B's and C's due to only requiring a narrow

alleyway to clear the strong back tube of the D frame. The D had

about a gallon extra fuel capacity due to it's tank belly pan

configuration. The factory Lightnings were all custom clearanced

as to carburetors.

The soundness of the tank is

most important. Does it leak? Does it contain rust?

How much body putty is on the tank, if any? Will it require a

tank liner application? Are all of the tabs correct in separation

width? Does the tank still retain the tire pump bracketry?

Prior to checking for leaks on

a tank that's been setting for a long period of time, it's a good idea

to wash the tank innards with muriatic acid. The muriatic acid

will attack those tiny stubborn rust particles that may be plugging up

a pin hole in the gas tank that's not detected until a week later when

you're 100 miles away from home on your first ride after

restoration. Make sure when you use muriatic acid that you use

gloves and eye protective gear. You MUST neutralize the muriatic

acid. Failure to do so will ruin the tank. Neutralization

can be done with a garden hose placed in the tank running, to allow a

six hour or more purge. Now with a light and a mirror, determine

the condition of the tank innards. Fill the tank with

water. Plug the two drain bungs. Make a quick gas cap with

a fitting of some sort, that will accept a controllable air hose.

Pressurize the tank to not more than 1 1/2 lbs. Dry

off any water spillage with a blow dryer. Hold the pressure for

at least 5 minutes. If any leaks are detected, repair externally

as required. Gas welding is the best method. Brazing is the

last resort, as sometimes brazing fluxes. Don't allow brass to

steel marrying. Brazing may hold for as much as a month or so,

but eventually gasoline liquefies the flux between the steel and brass

surface, and a leak is inevitable. The same problem occurs with

some silver solders, and some lead solders as well.

Go over the entire tank with a

pneumatic palm sander to remove all the paint. If there's no

primer underneath the black or red, or in the rarest of rare cases,

blue tank, it will more than likely be the original paint, as the gas

tanks were originally dipped without primer in the case of the black

tanks. I'm not sure about the red or the rare blue, they might

have been spray painted, and could have been primered. If

excessive body putty is detected after removal of all paint, a

determination is necessary as to whether a portion of the bottom of the

tank has to be removed for an access hole, to hammer and dolly back

into shape. If the bottom must be opened, use a thin blade metal

cutting saber saw. When reaffixing the metal door, first drill a

series of 1/8" holes, 1/4" away from the edge of the hole in the tank.

usually 4 will suffice. Cut 4 metal tabs from 16 gauge steel

sheet, approximately 1" long, 1/2" wide. Use needle nose vise

grips to clamp the tabs to the opening. The tab should protrude

1/2". Gas weld the tab in position with a button weld at the 1/8"

drilled hole. With the tank upside down, position the door in

place. Start the weld of the door by tack welding at the four tab

areas. This helps prevent any warping that may occur when final

welding is completed. Retest for any weld leaks. It's a

good idea to use a modern day tank liner. Make sure the

directions are followed, and most importantly, note whether the maker

states that the liner is impervious to alcohol. The reason for

this is that modern day fuels often contain a small percent of

alcohol. Around 10% I believe. Prior to installing tank

liner sealant, put a few nuts and bolts in the tank and rattle them

over all welded areas to remove weld slag. Clean weld slag

thoroughly from gas tank.

Next the tank must be fitted

to the frame. There are four mounting points, the rear being a

Siamized mounting system. There are four rubbers, front tank ears

right and left, and two rubbers, upper and lower at the rear. A

common problem with Vincent gas tanks is that the foreword ears, and

sometimes the gas tank itself, has been squeezed together, decreasing

the distance between the two tank mounting ears. In the Vincent

motorcycle parts list book, MO19 shows FT80, the front tank rubber,

pointing the wrong direction. The larger diameter of the rubber

should go inboard against the steering head casting. If the

rubber is installed incorrectly, the shouldered bolt puts pressure on

the tank, bending the ears. With new rubbers installed properly

without the tank, measure with calipers the distance from the large

diameter shoulder of the rubber left and right. Measure the fuel

tank flanges. The flanges should measure 1/8" less than the

rubber shouldered distance. This will allow, when installed,

1/16" crush on either side, allowing proper elasticity of the rubber

mounts. Too much crush reduces elasticity. A portapower

with a scissor tool can be used to open up the tank ear distance.

Now the rear tank

rubbers. First check to see that the tank is installed, and front

rubbers are tightened to full tube lock of shouldered bolt with washer,

and the two tank rear mounting slots are wide enough so that the

retaining bolts can be screwed in without touching. A 1/32"

clearance here would be a minimum. Install the upper and lower

pads. Now with washers, tighten the two retaining bolts where the

oil tank flange marries snugly to the bottom rubber pad, and the rubber

pad marries snugly to the gas tank flange, and the top rubber marries

snugly to the gas tank mounting flange, and the two washers are snug

against the upper rubber mount. Turn the bolts two additional

turns. This will provide the proper crush, and elasticity will

still remain. Of course when the tank is painted (which I'll

cover in segment (2) of gas tank restoration) and installed, the two

retaining bolts will be safety wired in an X pattern.

The last thing is to size the

aluminum spacer at the rear bottom of the tank to length. Too

short a spacer will cause stress on the tank when tightened, and

eventually will cause weld cracking. If everything is done

properly, you'll be able to firmly grab the tank on both sides, and

when twisted, will feel a movement. This movement provides enough

elasticity in your rubber mounted tank to prevent harmonic vibration

cracks to your newly restored tank. Max

Lambky 8/11/2010

Seat

Base: Marine

ply is excellent, the reason for this is that each lamination or layer

of wood is perfect, no holes are left in it, and the knots are very

very

tight leaving absolutely no air holes between the layers. the

quality

of the material is very good to excellent and the adhesive used - is

not

water based - therefor very resilient to water. there are many other

types

of wood laminates that are made with these characteristics now days

such

as Multi-laminates where there is a greater a amount of thinner

laminations

therefor increasing the structural integrity of your plywood. The best

thing you can do is take a trip to your local 'exotic wood' or fine

lumber

store - you wont find what you need at the 'Home' type hardware box

stores,

find your local wood place and talk to the folks behind the counter -

they

often have offcut sizes , and you can ask about the adhesive types as

well

as the quality of the laminates. I've got some if you cant find

anything

that i can mail to you enough to make your seat , but i'm sure the

postage

would cost more than buying it locally. after you've made the wood

choice,

as indicated by others use a high end sealers (you could stain it black

while you're at it if you so choose) drill all your holes etc, finish

machine

the blank and the seal it , and for good measure, when you're

done,,,,seal

it again. marc 6/2/09

Tank Bag:

http://www.fieldsheer.com/site2009/ff/productspage/EiffelTankBag.htm

Bruce

Metcalf

5/15/09

I have a "standard" Eclipse

tank bag which was a hand me down from

another Vin owner. It works very well with the standard Vincent tank as

far as the mounting straps go and is quite stable but I would recommend

a tank cover if you want to protect a nice paint job. Many years and UV

light have clouded the clear vinyl cover of the map pocket somewhat on

mine but otherwise it has proved pretty robust any I particularly like

the side pockets for easy access to stuff. Like a camping tent one has

to spray it with a good water repellent from time to time to make sure

contents stay dry.

The bag is large enough that it covers the gas

cap so one has to make an air tunnel (mine is carved out of a chunk of

ps foam) so as it does not block the breather. At refueling stops the

bag

has to be loosened on the front straps to allow access to the gas

cap.

Tim Holcroft 5/15/09

I originally had my

tank

cracks brazed, but that was before TIG

was available. I now have them TIG welded. In either case I drill

a 1/16 inch hole at the

either end of the crack to stop further growth

then have the tank brazed or TIGed. John Mead 4/16/09

Petrol tank leaks:

When they start leaking there the problem is in the forward tank

mounts.Good

idea to change rubbers frequently;don't reuse the old ones if they are

hard. Bones has a pressure tester for Vincent tanks.He submerges

them and pumps in a little air. Also be careful welding

tanks.A

guy I respect saw one blow up after 20 years!! You can pump in

exhaust

fumes to eliminate any oxygen. Somer 4/16/09

Good point about the need

to purge the tank during welding. I

use

a small table outdoors for welding tanks, and back my truck up next to

it. A 1-meter length of VW hot-air heater tubing (as used on old

beetles

to get air from the fan shroud to the heater boxes) connects 1 tailpipe

to the filler neck. Petcocks should be removed to give as much flow as

possible. Be wary of pressurizing the tank (especially automobile

tanks:

1 psi = 144 pounds of push on each square foot of tanks surface, so a

little

pressure can do a lot of damage.) I also wear a leather welding jacket

and a full face shield; it’s hot, but I know I’d be hotter if it

flashed.

Tom Volkmann 4/16/09

Petseal sloughing off with Methanol:

One of the Scots members has a B Shadow which has suffered in this way

(with "Old Petseal"). The flakes were very thin, maybe 15 -30 thou,

just

the right size to break up and plug the fuel system. I used a coating I

bought from Frosts, about 5 years ago, called something like K9P. So

far,

so good, run on unleaded, with the occasional belt of Avgas. The

only practical difference between ethanol and methanol is that the

first

can be drunk, the second can't. I think "methanol" is a

contraction

of "methylated ethanol". I don't know if that is different from

"methylated

spirits" (meths) but my late father-in-law used to start the 175

Francis

Barnett on which he went fishing on meth, then changed over to paraffin

(kerosene) once warmed up. Money were tight in them days... You can

make

your own ethanol (hundreds of Norwegians do) from sugar and yeast. It's

been calculated that if all the yeast sold in Norway was used to make

bread,

every Norwegian, man woman and child, must consume 18 loaves a day. Of

course I don't for one moment suggest you drink it, put it in your

vehicle

and save the planet. I pass over in silence making a fuel with

ecological

pretensions that used neat gives about 7 mpg in a 500 cc race motor. If

I were a cynic I'd say it was another way of subsidising farmers. But

I'm

not, so I won't. Sunbeam 4/6/09

Ethanol has

2 carbon atoms & methanol only 1 carbon. If a chemist heard you

saying

"methylated ethanol" then he might assume you were

talking about Methy Ethyl Ketone or alternatively you didn't

know what you were talking about. Many chemicals were used to

"denature"

ethanol

& 10% Methanol was the most common but Isopropyl alcohol was also

used. It was all about excise duty on the pure stuff but

not on the denatured product. In England they used to put a blue

dye in it but here in Australia it is clear. Alyn of

Thirroul

$/6/09

Seat Hump:

I took a piece of 5" stove pipe (opened up), traced and cut the profile

from the "seat well", hammered the perimeter flat and the job was done

in 10

minutes. Galvanized steel as well.

It could not have been any easier. Richard

Friedman

2/27/09

When you're putting

your

tank back on a useful tool is a piece

of 3/8" diameter mild steel with the end turned down to 1/4" diameter

and

the nose

tapered. You put it through the rubber on the

first side and wriggle the pilot into the tapped hole which is then

lined

up to accept your piloted

shoulder bolt, which you don't tighten fully.

You then go to the other side and repeat the process. Fit the bolts at

the rear of the tank before you

finally tighten the front ones.Roy Cross

2/20/09

Getting the rust out:I

have attached a 12"square of good quality plywood to a device

consisting

of a 6" X 6" plate of 1/4" steel welded to a 14" long piece of 1" o.d.

iron pipe. I firmly attach the tank to the plywood panel..insert

appoximately

1/4 lb. of ceramic media and 2 cups of dish washing detergent. This

fiendish

thingee is then locked into the three jaw chuck( having been inserted

through

the spindle hole from outside of the headstock). After Double Checking

for security I set the lathe on 'back gear' @ 3rpm. I let it run

for three hours at a time...never when I am more than half the shop

length

from the set-up... and, eventually and with minimum risk or violence

and

No viscous acids; Bob's Your Uncle... Dave R. 2/18/09

Gettting the gum out:

In any event, on Oct 4th, I bought a Shadow basket including its fuel

tank

a third full of 32 year old high test and adding to the challenge,

"indifferently"

stored during that time, leaving an extreme example of the "lacquer"

gum

you referred to along with some superficial rust in the form of a

pungent

sludge. I too wanted to preserve the exterior finish - not

because it was original - but to add to the planned antiqueing of this

machine to which now looks like a comfortable well worn but polished

English

gentleman's boot here. The finish? Nothing spectucular, a

Conway's

job superbly applied prior to 1959, but lined in gold paint rather than

gold leaf. To add to the challenge, 32 years of regular

applications

of cat urine to this tank had turned the single stage enamel clear coat

- a popular top coat finish technique of the time - into a milky vinyl

type consistency exposing the fragile lacquer color coat and decals

beneath

it.

As I've done over the years with Indian tanks (soldered not welded)

and on my Red Rap tank. I filled it half full with lacquer

thinner

and a lb of 1 1/4 zinc plated roofing nails sat it on the work bench

and

then made a daily habit as I passed by on the way to work with

the

machine on the lift of slowly agitating it then letting it sit.

Don't

recommend bb's, not enough mass, too smooth and have a tendency to want

to stick where any gum remains. Zinc plating on roofing nails is done

very

thick to act partially in a self-sealing capacity when damaged (hammer

blow) and is rather soft. The perimeter edge of the head and the sharp

end do their job with less "violence" so to speak than required with

other

metal based media when agitating by hand. Having less mass than a

bolt or nut, they are far less prone to dent your tank.

Unless you have pin holes leaks which might explain the presence of

a sealer in the first place, then your only vulnerability with a

solvent

like lacquer thinner is from the vent on your cap (seal it) and when

your

pouring in/draining off. I have a long tube which I affix

to

the filler neck for both activities and apply a thin layer of grease as

a sacrificial barrier around the filler neck to act as a sacrificial

barrier

for the short time it takes to reach for a rag if any splashing might

occur.

Peter Williams 2/18/09

Removing petrol tank liner:

Old liner material will have to be removed before any effective repair

can be made. I would attempt to remove some small bits of the liner for

diagnostic experimentation with solvents. Start with Berryman, brake

clean,

carb clean etc, and if none of those work, try acetone, NMP or TCE. MEK

should be a last resort. (They don’t call it Methyl-Ethyl-Death for

nuthin!)

Once you have a solvent that works, even if it only works very slowly,

add a carton of BBs to the tank, and use them as a mechanical scouring

agent to work with the solvent. Be patient; it may take a while. If the

stuff is really stubborn, tumble the tank by wiring it to a car wheel

driven

by the shaft of an electric motor. Email me if you want more info on

how

to do this. (This is how I tumbled my UFM.) Beware that your pinholes

may

get bigger as you do this. I will also caution you that

some of the aforementioned solvents are highly toxic and/or highly

flammable.

Make sure you download a MSDS for whatever you are working with to

avoid

hurting yourself or burning your house down. Nitrile chem. gloves and

goggles

should be the minimum for safety gear. Tom Volkman 2/16/09

(Once

again....thevincent.com does NOT recommend use of any

solvents.

Use of solvents is better left to professionals as some are reported to

be carcinogenic, flammable and/or highly toxic.)

RK Leighton offer replacement

squabs

for

Vincent

seats, along

with

replacement

bases (Complete with all strengthening bars).

Phone:

(44+) (0)121 359 0514 or

E-mail:

info@rk-leighton.co.uk Neil. 1/6/08

Petrol

tank

tap threads: 1/4"

BSPP (British Standard Parallel Pipe) with a major diameter of 0.518"

and

19 threads per inch. Not to be confused with American 1/4"

National

Pipe Thread (NPT) which has a major diameter of 0.540" and a pitch of

18

tpi. Ken Targett 9/17/08

Gold Leaf Pin Striping

on the tank: These were all hand

painted using lining brushes and they vary from a quarter to five

sixteenths.

Anything within those sizes looks good. Roy Cross 9/4/08

Tank and UFM Cleaning

- Sealing: Rusteco is

good.

http://www.rusteco.com/auto.htm

It ain't cheap, but can be reused. I've had a

big bucket of it for a couple years and have used it about 3 times,

it's

still doing its thing. Safe, too. I am not big on their gel product,

though,

but maybe I didn't use it correctly. You'll like that liquid

stuff.

Bev Bowen 8/18/08

When I restored my Prince 5 years ago there was

corrosion

in the petrol tank. Having clean it

out

as best as I could, I lined it with a white epoxy compound two pack

product,

very successfully. A great advantage being you can see the tank

contents

very easily and any sediment that can later accumulate. Be careful to

mask

off the petrol tap threads before carrying out the process as they are

hell to clean up afterwards. The final result is excellent and very

durable.The

supplier is :-

C.Wylde & Sons Ltd,

1 Roundhay Road,

Leeds LS8 5AJ (sorry I don't have their phone

no.)

Product :- Flo-Liner White Epoxy Compound ( a

pack contains 1 large tin and 1 small tin and is sufficient to treat a

Vincent tank)

Paul Craven. 3/11/07

There were 4 articles in the

'Throwing

Light on Some Obscure Components' Series describing gold

leaf lining and transfers; the

relevant

MPH editions between April and July 94 (was it that long ago?) were:

No. 543 The Petrol Tank

No. 544 Enclosed D Lines

No. 545 Enclosed D Transfers

No. 546 Applying Gold

Leaf

Frank Griffin 12/2/06

Tank Sealer:

The best out there is a product called Red Kote. You can get this

through

some commercial truck stores or radiator shops. Holt BMW offers

this

service for around $80 with about a 2 week turn around. Your

original

paint will not be harmed. It's money well spent as it is a PITA

to

do this. If your tank already has a white liner in it it will not

work. Red Kote is not compatable with Kreeme which is junk

anyway.

Some folks use a product called POR wich is still not as good as the

Red

Kote. Plus the Red Kote liner is reddish and it a more of a rubbery

coating.

. Holt BMW/Ducati, 15530 US Rt. 50, East Athens, OH

(740)593-6690.

BMW message board. 12/08/02

Removing Tank Sealer:

When

I acquired my bike, its fuel tank had been coated (probably with Kreem

although I'm not certain). Surface prep had evidently not been

done

correctly, as rust had loosened the coating and chunks were coming loose

and ending up in the carbs. This did not

enhance performance, and created a fire hazard when debris held the

float

needle open and the carbs overflowed.

Anyhow, Kreem advised me that their product is

soluble in acetone, so I bought a gallon at the Home Depot. This

worked very nicely; it actually dissolves the coating rather than just

softening it, so you can remove all the material if you're

patient.

Also, acetone is one of the less-dangerous solvents to work with.

I'm not sure how universal it is with regard to other brands of

coating,

but it may be worth a try. Dave Hartner 8/3/02 (thevincent.com

does NOT recommend Acetone as a solvent. Use of Acetone is better

left to professionals as it is reported to be carcinogenic.)

Your front tank

bolts can and should only be done up

to

the shoulder, just captivating the rubber, the tank sits on this. No

way

should the tank be clamped by the front bolt. All the clamping is done

at the back, by the two 5/16 bsf bolts two rubbers and a top plate of

steel.

The rubber should be fitted with the head between the headstock and the

tank, the bolt should have a washer 3/4" diameter under the head. and

the

shoulder bolt should be 3/4" long under the head. So that when the bolt

is done up tight to the shoulder, it lightly compresses the rubber to

expand

in gently and grip the tank. should have no effect in clamping the tank

at all. Trevor Southwell 07/05/01

Bob Culver of Letchworth, UK

(see

Drat engine case advert in a year old MPH) had Dunlopillo make some

NEW seat foams in the right material a

year or so back. Right shape and "weight" and standard length. Real

labour

of love and very expensive at around £50 each. not stocked by

VOCS

as they would rather stock something cheaper apparently. Arthur

Farrow

12/29/00

Bob Culver has run out of the Dunlopillo

seat foams as of not very long ago. He

is having some polyether ones made subject to getting the underside

geometry

of the squab of the correct contour, and the chemical composition of

the

mix optimized. About a month he said and about GBP50 delivered UK. His

number when I rang today is: +43 (0)1462 673705. You may get it for

this

price in US cos you won't pay the VAT. The seat arches are available

from

West Country Sidecars in glass fibre (see MPH). The rest you can

make with your bare hands. Ken Tidswell 02/27/01

The short (old) style seat

is (about) 12" from the nose to the first high point and 22" from nose

to tail. The long seat is 15.5" to the first high point and 26

overall.

On this one the nose appears extended up the tank a bit and this part

of

the extra length

doesn't help my own big end much. I find it less comfortable than the

short one also because the foam comes up more steeply to the middle

crest

and makes it harder for one to slide back against it. Mike Hebb

12/29/00

Large

Petrol Tanks:

The large tank fitted to

Charlie Cannon's bike is not a Montlherry tank as it is the wrong

shape. I have been fortunate enough to see an original Montlherry tank

some time back, belonging to Pat Highsmith from Northern California. (currently

owned by Jim Baltusnik 5/06) These tanks

were

identical at the front to the standard tank but were raised at the rear

by a couple of inches to give a capacity of about 4 1/4 UK gallons. On

side profile the top of the tank was almost horizontal. Charlie's tank

is a "one off" from an unknown source.

Large

Petrol Tanks:

The large tank fitted to

Charlie Cannon's bike is not a Montlherry tank as it is the wrong

shape. I have been fortunate enough to see an original Montlherry tank

some time back, belonging to Pat Highsmith from Northern California. (currently

owned by Jim Baltusnik 5/06) These tanks

were

identical at the front to the standard tank but were raised at the rear

by a couple of inches to give a capacity of about 4 1/4 UK gallons. On

side profile the top of the tank was almost horizontal. Charlie's tank

is a "one off" from an unknown source.

Things start to become interesting when you

talk

about the correct locations for the gold lines and transfers. Series

C's

are fairly straight forward, if you took the mean average of all the

tanks

you could measure then you would not be far out with the positioning on

the transfers etc. The series B tank was something else. When I

first

started painting tanks I went to Alan Lancaster's pub where on the wall

was an original advertising poster from the factory. It had photographs

of both sides of the same Series B and I had brought all I needed to

faithfully

record the positioning of the gold lines etc. I was wasting my time,

this

show model had the HRD about 1 inch out, in relation to the opposite

side.

In truth you cannot see both sides of the tank at the same time and the

factory had not expected someone to inspect their poster years later

with

a slide rule.

I have since taken detail measurements from

several

so called original tanks and yes they are different, the gold lines

were

applied by hand without the obvious use of a template. Very few people

will be able to draw an identical arch to the left and to the right

freehand,

so don't let anyone tell you the lines on your tank are wrong.

A word of warning for anyone about to use

Series

D Black Shadow transfers from the spares club. They look OK but

over

the years the water soluble glue has disappeared from the backs and it

is only possible use them by painting them with a replacement glue.

For anyone who is interested the older

tradesman

in Southern England (as described by Robert Watson) is still

producing

4 3/4 gallon aluminum petrol tanks to my design but they now sport

flush

aircraft fillers as the twist neck type appear unobtainable. If you

know

different please mail me with the source. If you are interested in

getting

one (photos available) then order early as the old guy only works one

day

a week. Paul Adams 12/05/00

Vincent Colours: I've

actually seen pictures of one of the blue ones. It was called "Egyptian

Blue".It was a Touring Rapide. A few years ago, some NOS blue touring

fenders

turned up. I also came across an orginal Shadow that was sent over for

the New York show. It had chrome hardware(this was common on show

bikes)

and a blue tank. Over the years I've also come across original Touring

Raps that had red fenders and tanks. Charlie Taylor told me about

having

a Shadow go through his shop that had an orginal red tank on it. Red

was

not popular then. I've found several red raps over the years that were

repainted black upon removal from the crate. Some red ones also had

white

seats. There were 17 Red Comets made, making them one of the rarest of

all Vincents. Somer Hooker 12/09/00

Rare Colours:

Perry

Osgood's

Shadow

is

a Red" White" Shadow with a 1A number. There is

another one too. One

of my friends found it a few years ago.He

happened

to pull in into a service station on his Vin..A guy in there commented

that he knew where one of those was(Meaning a Vincent)It was still in

the

hands of the orginal owner. See what happens when you RIDE your

Vin.

Somer Hooker 12/09/00

Rare Colours:

On one of the sets of cases I just recorded for Gordon (Mr numbers)

Powell

he said it was a "Red/Black" Rapide, which "I think the red/black ones

were black frame and fork parts with red tanks and mudguards

(fenders?)".

Perry Osgood's bike was originally sold in Vancouver and has a /1A/

engine

number, painted red with polished cases but would question the touring

statement John! Although I'm sure Gordon or Perry could clarify if you

really wanted to know. I question it as Perry does not have

touring

fenders on it and I know he wanted a very original restoration.

Robert

Watson 12/09/00

Return to:

thevincent.com

(see

paint section too..)

(see

paint section too..) Large

Petrol Tanks:

The large tank fitted to

Charlie Cannon's bike is not a Montlherry tank as it is the wrong

shape. I have been fortunate enough to see an original Montlherry tank

some time back, belonging to Pat Highsmith from Northern California. (currently

owned by Jim Baltusnik 5/06) These tanks

were

identical at the front to the standard tank but were raised at the rear

by a couple of inches to give a capacity of about 4 1/4 UK gallons. On

side profile the top of the tank was almost horizontal. Charlie's tank

is a "one off" from an unknown source.

Large

Petrol Tanks:

The large tank fitted to

Charlie Cannon's bike is not a Montlherry tank as it is the wrong

shape. I have been fortunate enough to see an original Montlherry tank

some time back, belonging to Pat Highsmith from Northern California. (currently

owned by Jim Baltusnik 5/06) These tanks

were

identical at the front to the standard tank but were raised at the rear

by a couple of inches to give a capacity of about 4 1/4 UK gallons. On

side profile the top of the tank was almost horizontal. Charlie's tank

is a "one off" from an unknown source.