Vincent Technical

Sections: -Serial

Numbers/Production-

Photo Gallery of Models - Brakes

- Engine

Overhaul - Vincent

Engines - Wheels/Fenders

- Instruments - Transmission

- Clutch - Magneto

- Tank/Seat - Suspension

-

Tools - Norvin

-

Electrics-

Carburetors

- Misc - Links

-Vincent

Parts/Services Suppliers - Polishing/Cleaning

- Shipping Vincents-Electric

Starter - Paint/Transfers

The McDouglator Solves Vincent Motorcycle

Charging Problems

By Carl Hungness

I

have discovered an alternator that in my estimation virtually solves any

problem we may have encountered with a reliable charging system for our

Vincent motorcycles. It will crank out 20 volts, 15 amps and 150

watts. The supplied regulator cuts back the volts to 13.8, perfect for

a 12 volt charging system. Best of all, the unit has been tried and

proven for the past 15 years on dozens of Vincent twins and a couple of

Comet singles. You do not need to modify or change anything on your bike

to install this alternator. Not only does it bolt right on but it has been

proven as reliable production unit on thousands of tractors world-wide.

I

have discovered an alternator that in my estimation virtually solves any

problem we may have encountered with a reliable charging system for our

Vincent motorcycles. It will crank out 20 volts, 15 amps and 150

watts. The supplied regulator cuts back the volts to 13.8, perfect for

a 12 volt charging system. Best of all, the unit has been tried and

proven for the past 15 years on dozens of Vincent twins and a couple of

Comet singles. You do not need to modify or change anything on your bike

to install this alternator. Not only does it bolt right on but it has been

proven as reliable production unit on thousands of tractors world-wide.

One John McDougall, a long-time VOC member who now resides in Vancouver,

British Columbia has re-developed a Kubota tractor alternator to give Vincent

riders all the power from a generating unit they would ever want.

The McDouglator as it is known, comes complete with a virtually indestructible

regulator. John has run the alternator unit in a drill press and literally

tried to ruin the regulator with no success in doing so. If you ever do

fry a Kubota regulator, you can buy a replacement in virtually any country

in the world. John discovered the Kubota unit back in the early 1990’s

when it was advertised as being a replacement for early Harley-Davidsons.

His pal George Hacking, who has racked up some miles on a Vincent himself,

brought the unit to John’s attention. The original manufacturer of the

conversion made a fateful decision in his version, as he believed the bearings

on the front of the alternator would keep oil from entering the unit itself.

However, oil from the timing chest on the Harley did seep into the rotor

area thereby negating its performance. Basically, the man who developed

it for the Harley took the Kubota unit, knocked the mounting ears off of

it, put in a couple of heli-coils and bolted it to the Harley. The oil

found its way past the sealed bearings and rendered the unit inoperable.

McDougall, a pipefitter by trade and accomplished machinist set about to

make a drive system that would dovetail with usage on the Vincent. In all,

he has made three separate drive units to accommodate the Series “B”, “C”

and Comets. The geometry of each is different thereby necessitating engineering

for all three separate bikes.

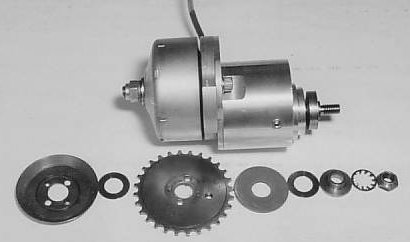

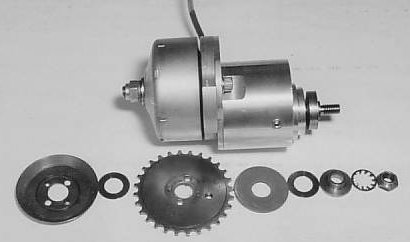

What he came up with is a small gearbox he machines from billet

that ultimately turns the Kubota at one and one half-engine speed. Our

original generators were driven at one and a quarter engine speed. John

cuts his own gear blanks and has a gear cutter finish them. The drive gear

has 18 teeth, the driven gear 15. The gears are literally the same as we

use in the timing chest of our Vincents, 16 DP (diametrical pitch). His

gearbox carries 30 ML of oil you fill through an Allen setscrew and care

must be taken not to tip the alternator (during installation) so the oil

has no chance of reaching the rotor. This act presents no problem as the

unit slides past all existing lubricant hoses with ease.

Although John’s first incantation of his modifications and attendant

gearbox served well in his 12,000 mile test on his own ’54 Shadow, he noted

the inertia loads caused by the unit were extremely high. He was about

to ruin the primary chain. Because the unit is being over-driven at one

and a half times engine speed, if you snap the throttle shut at say 6,000

RPM and the Kubota is running 9,000 RPM, it tries to keep on going. This

action will beat the primary chain to death. John came up with a very simplistic

slipper clutch arrangement made up of steel washers that is about as foolproof

as the alternator itself. To install the Mcdouglator you utilize

the standard Vincent dynamo sprocket boss (PD 16) its oil thrower (PD28)

called an oil flinger in John’s literature. We discard the Dynamo Drive

Plate (PD17AS). You are supplied with a pair of hardened steel washers,

one that goes behind the oil thrower and another that goes on his shouldered

spacer. In-between the pair is what John is calling a Bellville washer,

a large conical washer whose cone face rides against our standard drive

sprocket. The oil thrower needs to have a pair of dimples punched into

its face via a dull punch that will index with the dynamo sprocket boss.

You are supplied with a shouldered spacer that aligns the whole plot along

with a drive end nut and star washer.

I sent my old boss to him along with the oil thrower and John tapped the

two dimples in, an act that you can surely do yourself. The

resultant stack of washers along with the Bellville washer allows the drive

assembly to slip when it needs to. You install this AC alternator same

way as you would your stock generator and torque the sprocket nut to 35

lbs. The rotor nut at the other end of the alternator has already been

torqued in place at 60 lbs. After installation you can check the

movement of this slipper clutch arrangement by holding the sprocket nut

with a wrench (11/16) and the alternator itself will still turn.

Although the rotor end of the unit appears to be large, the entire assembly

slipped into place without touching anything. You move no hoses, make no

modifications. The smooth rotor cover actually spins out in the breeze

but it would take a real moron contortionist to inveigle his fingers to

the spot on the bike where the cover is actually spinning. John has supplied

dozens of the MacDouglators over the past 15 years and they are all giving

dedicated service.

I sent my old boss to him along with the oil thrower and John tapped the

two dimples in, an act that you can surely do yourself. The

resultant stack of washers along with the Bellville washer allows the drive

assembly to slip when it needs to. You install this AC alternator same

way as you would your stock generator and torque the sprocket nut to 35

lbs. The rotor nut at the other end of the alternator has already been

torqued in place at 60 lbs. After installation you can check the

movement of this slipper clutch arrangement by holding the sprocket nut

with a wrench (11/16) and the alternator itself will still turn.

Although the rotor end of the unit appears to be large, the entire assembly

slipped into place without touching anything. You move no hoses, make no

modifications. The smooth rotor cover actually spins out in the breeze

but it would take a real moron contortionist to inveigle his fingers to

the spot on the bike where the cover is actually spinning. John has supplied

dozens of the MacDouglators over the past 15 years and they are all giving

dedicated service.

On my Series “C” it was necessary to take a half-round file and give

the top of the generator clamp a bit of clearance for one of the Allen

bolts that sticks out the front of the drive gearbox. John supplies you

with a paper template you lay on the clamp itself to show where to remove

some material. It did not take me five minutes to make clearance for the

Allen bolt. You would never know the clamp was filed unless I told you

so.

John McDougal has spent more than a morning coffee break engineering

the unit into place. I for one am enamored with the idea of installing

something modern, unobtrusive on our machines that enhances performance.

This alternator seemingly puts out enough juice to weld with. He

also supplies a small aluminum plate that bolts on top of the clamp that

will accommodate the stock Kubota alternator. Of course the Kubota regulator

is a big squarish thing, finned to relieve the heat. I went through a few

machinations to hide it under my battery carrier and re-installed my old,

cute little Miller cover that is now just a dummy box. It will hold one

spark plug and/ or a variety of nuts, bolts, wire or rubber bands if you

so desire. Consequently, when you look at my bike as you walk past, all

you really see is the stock Miller regulator cover in place as it should

be. I made simple angle bracket to hold the Kubota unit under my battery

carrier and utilizes the same bolt that holds the battery strap to keep

it in place. I mounted the ground wire to it as well. Naturally I have

to fiddle a bit to get the wiring in, but I am used to that as all my wiring

is hidden in my handlebars and out of sight to the viewer. I run a beautiful

little Buell switch that handles the turn signals, horn, hi-low beam and

flasher. So it has a lot of wires in it. Plus I have heated grips and a

kill button on the bars with nary a wire in sight. My heated vest wiring

is under the seat.

The price of the MacDouglator is a bit more than an Alton, around nine

hundred U.S. dollars. I can tell you that with a 60 watt headlight bulb

and running lights that double as turn signals on, the Kubota put out an

immediate 2-4 amps just above idle. You just touch the throttle and it

is putting out more wattage than we will ever need. I did not have the

same luck with the Alton.

The Alton is surely a fine device, but it runs at one and a quarter

engine speed and my experience was that it needed quite some RPM in order

to get the job done on a Vincent. Nevertheless, there are literally dozens

of Altons in use on Vincents but it seems only reasonable we draw a comparison

to the two. When McDougall’s pal George Hacking brought the Kubota to John’s

house, John noted, “You ain’t going back home with that thing you know.

Leave it here. I think I can make it work on the Vincent and it looks like

just what we need.”

He was right. We need all the John MacDougalls out there whittling

away to make parts that keep our machines up to date. John is also one

of the driving forces behind the fabulous Max Lambky streamliner project

and is responsible for some of the internals that are never seen. He is

one of the unsung heroes who has put his journeyman’s hand in the streamliner

project as he is in love with the idea of seeing this great streamliner

take a record home. He has also developed an ignition system for

the Vincent utilizing Harley-Davidson parts that we will tell you about

in the future. Because John is a hobbyist he doesn’t advertise his products

so you have to hear about them by word-of-mouth. He can be reached at his

home in Vancouver, B.C. at 604 327-1019.

Return to main page of:

thevincent.com

I

have discovered an alternator that in my estimation virtually solves any

problem we may have encountered with a reliable charging system for our

Vincent motorcycles. It will crank out 20 volts, 15 amps and 150

watts. The supplied regulator cuts back the volts to 13.8, perfect for

a 12 volt charging system. Best of all, the unit has been tried and

proven for the past 15 years on dozens of Vincent twins and a couple of

Comet singles. You do not need to modify or change anything on your bike

to install this alternator. Not only does it bolt right on but it has been

proven as reliable production unit on thousands of tractors world-wide.

I

have discovered an alternator that in my estimation virtually solves any

problem we may have encountered with a reliable charging system for our

Vincent motorcycles. It will crank out 20 volts, 15 amps and 150

watts. The supplied regulator cuts back the volts to 13.8, perfect for

a 12 volt charging system. Best of all, the unit has been tried and

proven for the past 15 years on dozens of Vincent twins and a couple of

Comet singles. You do not need to modify or change anything on your bike

to install this alternator. Not only does it bolt right on but it has been

proven as reliable production unit on thousands of tractors world-wide.

I sent my old boss to him along with the oil thrower and John tapped the

two dimples in, an act that you can surely do yourself. The

resultant stack of washers along with the Bellville washer allows the drive

assembly to slip when it needs to. You install this AC alternator same

way as you would your stock generator and torque the sprocket nut to 35

lbs. The rotor nut at the other end of the alternator has already been

torqued in place at 60 lbs. After installation you can check the

movement of this slipper clutch arrangement by holding the sprocket nut

with a wrench (11/16) and the alternator itself will still turn.

Although the rotor end of the unit appears to be large, the entire assembly

slipped into place without touching anything. You move no hoses, make no

modifications. The smooth rotor cover actually spins out in the breeze

but it would take a real moron contortionist to inveigle his fingers to

the spot on the bike where the cover is actually spinning. John has supplied

dozens of the MacDouglators over the past 15 years and they are all giving

dedicated service.

I sent my old boss to him along with the oil thrower and John tapped the

two dimples in, an act that you can surely do yourself. The

resultant stack of washers along with the Bellville washer allows the drive

assembly to slip when it needs to. You install this AC alternator same

way as you would your stock generator and torque the sprocket nut to 35

lbs. The rotor nut at the other end of the alternator has already been

torqued in place at 60 lbs. After installation you can check the

movement of this slipper clutch arrangement by holding the sprocket nut

with a wrench (11/16) and the alternator itself will still turn.

Although the rotor end of the unit appears to be large, the entire assembly

slipped into place without touching anything. You move no hoses, make no

modifications. The smooth rotor cover actually spins out in the breeze

but it would take a real moron contortionist to inveigle his fingers to

the spot on the bike where the cover is actually spinning. John has supplied

dozens of the MacDouglators over the past 15 years and they are all giving

dedicated service.